The lithium battery market is very broad, with high added value, and electrode materials account for more than 70% of the cost, which determines the performance of lithium batteries. Main equipment for the production of lithium battery materials: mixing equipment, calcination equipment, crushing equipment, packaging equipment and testing equipment.

Among them, the crushing and grading equipment is at the end of the process, which has a great impact on the performance of the final product. Therefore, the processing of electrode materials is an important link. Due to the high price of battery positive raw materials, if the crushed products are unqualified or over-crushed, the yield rate will be reduced. It will be greatly reduced, and the loss will be very large. Therefore, whether the products produced by the crushing equipment can achieve narrow particle size, no over-crushing and large particles, and low fine powder rate are particularly important!

The crushing and grinding of electrode materials can use many crushing equipment, such as: grinder, pin-type sand mill, jet mill, etc. Among them, the jet milling equipment is second to none. The jet milling equipment has the characteristics of large production capacity, high degree of automation, fine particle size, narrow particle size distribution, high purity, high activity, and good dispersion, which fully meet the preparation requirements of electrode materials, so it is widely used. application.

Working principle of jet mill

The jet mill uses compressed air to form a high-speed airflow trajectory in the crushing chamber, so that the powder is crushed by impact, shearing, and friction. At the same time, due to the centrifugal force, the crushed product can complete powder classification in the crushing chamber.

According to the working principle and actual operating experience of the jet mill, the main safety issue involved in the crushing process is the harm of dust to the human body and the environment.

The finer the dust, the longer it stays in the air and the more chances of being inhaled. The larger its surface area, the stronger its chemical activity in the human body, and the more obvious its effect on lung fibrosis. At the same time, dust has a strong adsorption capacity. Harmful gases, liquids, and metal elements in the surroundings can be adsorbed on the dust and brought into the lungs, thereby promoting the occurrence of acute or chronic diseases.

In addition, dust may also cause an explosion after being dispersed in the air on a large scale to form a dust cloud. Generally, dust with a particle size of less than 5 μm has good dispersion stability in the air and can easily reach the explosion limit. If the shock wave generated by the local dust cloud explosion makes a large amount of deposited dust fly up and mix with the air, it may cause a secondary explosion. The dust explosion is seriously damaged, and it is easy to cause incomplete combustion and produce a large amount of carbon monoxide gas, which can cause poisoning.

Prevention and Control of Ultrafine Dust

1. Use dust removal equipment

For respirable dust, foam dust removal, wetting agent dust removal, ultrasonic atomization technology, composite filter bag dust removal, folding dust bag, wide-spacing electrostatic dust removal, etc. can be used. For dust explosion, wet dust removal or combined dust removal should be adopted.

2. Personal protective measures

Personal protective measures against respirable dust are mainly wearing masks. The protection methods of dust explosion include isolation, explosion venting and suppression, such as strictly prohibiting fire source, controlling static electricity, reducing dust concentration, strengthening ventilation, etc.

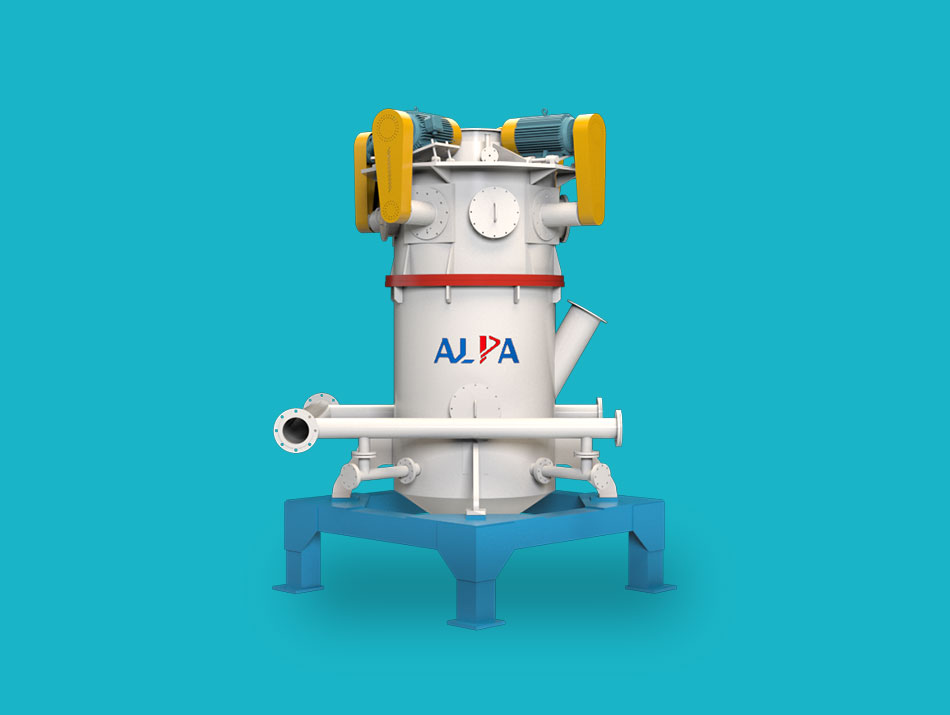

The jet mill production line independently developed and produced by Shandong ALPA Powder Technology Co., Ltd. adopts a special design and uses high-quality filter materials to reduce dust emissions as much as possible. The explosion-proof design can also be selected according to customer needs, and the whole system is sealed and crushed to achieve the purpose of less dust, low noise, clean and environmental protection in the production process.