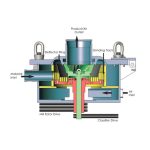

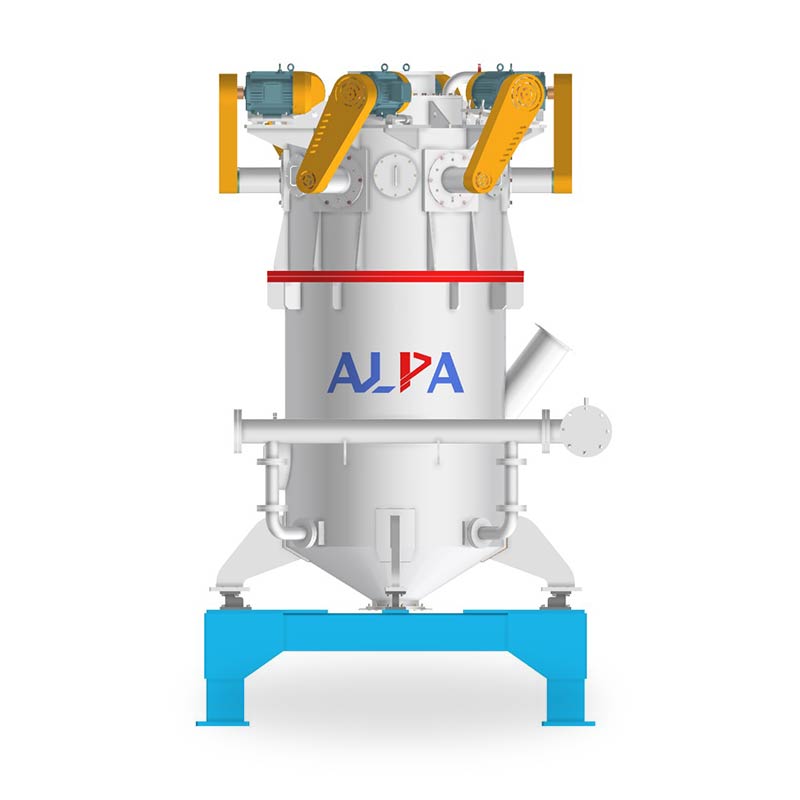

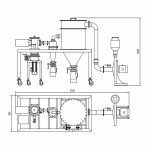

The material is uniformly sent into the grinding chamber by the feeding system, and is strongly impacted by the high-speed rotating grinding disc. At the same time, it is subjected to the centrifugal force to collide with the crushing ring gear, and is subjected to various comprehensive forces such as shearing, friction, and collision.

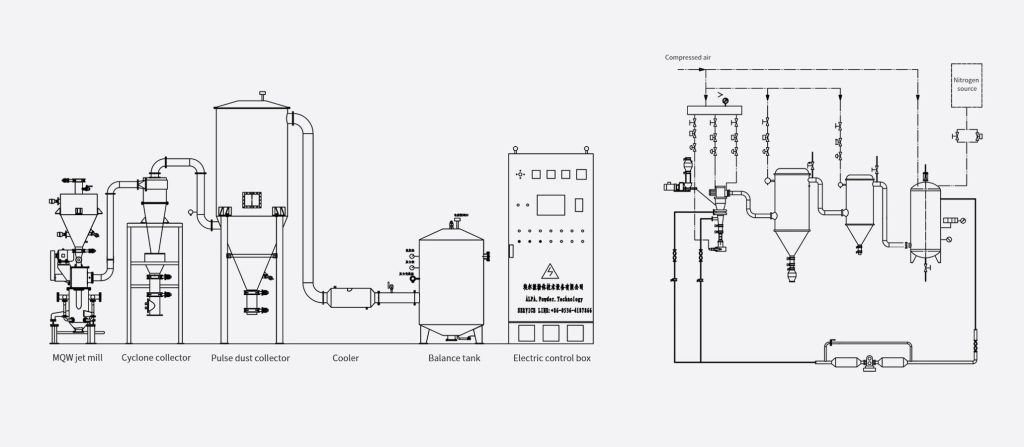

The material is ground, and the crushed material moves to the classification area with the airflow. The coarse and fine materials are separated through the classification wheel adjusted by the frequency conversion. The products that meet the fineness requirements enter the cyclone collector and the dust collector with the airflow for collection, and the coarse particles return to the grinding area to continue shattered.

– Whole ceramic protection,no magnetic substance.

– Optimized milling assemble,good ball shape,high bulk density.

– Humanization design,easy to change parts.

– Closed-loop system,no moisture increasing,nitrogen circle system available, extremely low oxygen content.

– Machine large change to meet different capacity requirement.

– Sintered plate filter available,filtering precision 0.1um and collecting rote up to 99.99%.

– Processing parameter memory and historical record query(intelligent control).

– Whole rotor with sintered zirconium aluminum ceramic.

– Separated zirconia ceramic gear ring.

– Customized zirconia sintered hammer.

– Whole air deflector.

– Discharge pipe upgrade to whole ceramic liner pipe.

– Imported LINATEX liner.

– No copper and zinc parts.

– Inner chamber of blower with SS304 coated PTFE.

– Return pipe anti-metal processing.

– PLC automatic control.

– Running:vibration sensor,temperature sensor.

– Validation document available.