With the vigorous development of the new energy industry, solid-state batteries, as the representative of the next generation of battery technology, have attracted much attention due to their higher energy density, better safety and longer cycle life. In the development of solid-state batteries, carbon materials play a vital role, and their application fields are wide and the prospects are broad.

Mainstream carbon materials include carbon nanotubes, graphene, conductive carbon black, porous carbon, etc., which can be used as electrode materials and electrolyte additives in solid-state batteries.

Carbon nanotubes

Carbon nanotubes have good conductivity, high specific surface area and excellent mechanical properties, and are mainly used as conductive agents in solid-state batteries. It can establish an efficient conductive network between active materials and between active materials and current collectors, reduce the contact resistance of electrodes, accelerate the migration rate of electrons, and thus improve the charge and discharge performance and rate performance of batteries. Especially in silicon-based negative electrodes, carbon nanotube conductive slurries perform well. Their high mechanical strength can improve the stability of silicon-based negative electrodes, make up for the shortcomings of poor conductivity of silicon-based negative electrodes, and effectively alleviate the structural collapse of silicon-based negative electrodes during lithium ion deintercalation.

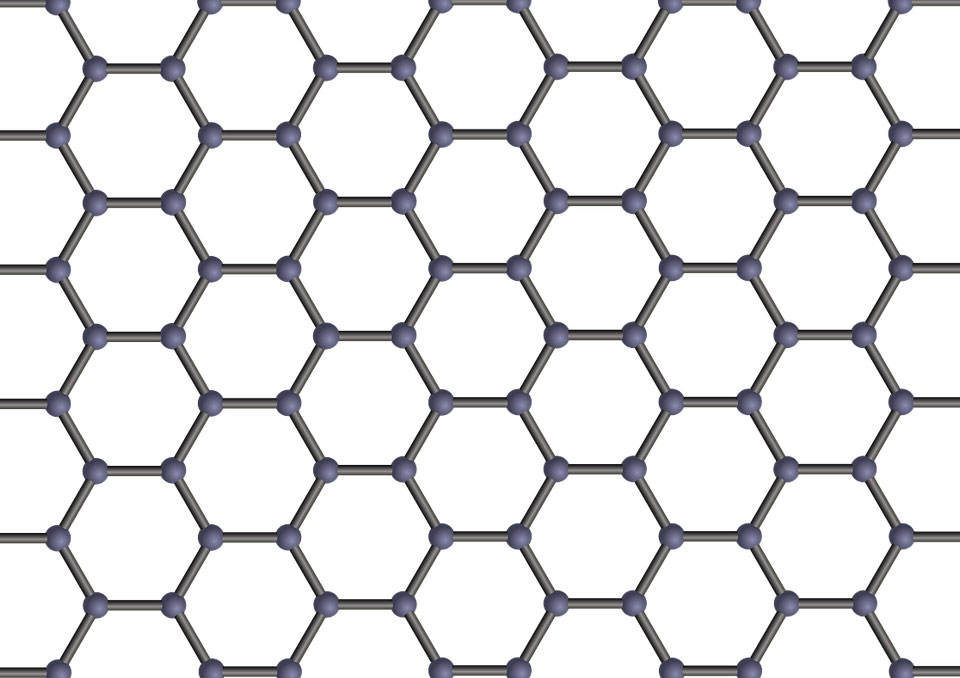

Graphene

Graphene, with its unique two-dimensional structure and excellent properties such as high electron mobility and high theoretical specific surface area, plays an important role in many aspects in the field of solid-state batteries. It can be used as an electrode material to improve the battery energy density and electrode structure stability; it can also act as a conductive additive to improve the battery charge and discharge performance and reduce internal resistance; it can also be used to modify solid electrolytes, improve ion conductivity and inhibit lithium dendrite growth; in addition, as a diaphragm material, it can enhance the mechanical properties and ion selectivity of the diaphragm.

Porous carbon

Porous carbon has a rich pore structure and high specific surface area, and can be used as a carbon skeleton material for silicon-carbon negative electrodes in solid-state batteries. Its quality is crucial for the production of high-quality silicon-carbon negative electrodes. The appropriate porous carbon structure can provide buffer space for silicon, improve the stability and conductivity of silicon-carbon composite materials, and can regulate its pore size, pore volume and porosity according to different application scenarios to meet the requirements of battery performance.

Conductive carbon black

Conductive carbon black is a commonly used conductive agent, mainly used in the positive electrode and some negative electrodes of batteries. It has excellent conductivity and high surface area, can establish a conductive network inside the electrode, improve the electron transmission capacity inside the electrode, and the rich pores help absorb electrolytes and build lithium ion migration channels, thereby improving the discharge rate and cycle stability of the battery.

In the development process of solid-state batteries, carbon materials have occupied an irreplaceable key position. They are widely used in electrode materials, electrolyte additives, etc., which significantly improves the performance of solid-state batteries. Many companies continue to focus on the research and development of carbon materials, constantly make technological breakthroughs, and promote solid-state battery technology to a higher level. In the future, carbon materials will lay a solid foundation for the large-scale commercial application of solid-state batteries, thereby promoting the new energy industry to a more brilliant stage of development and helping the green transformation of the global energy structure.