What do you think of when you think of silicon anodes? Large capacity, high volume expansion? As a new generation of lithium-ion battery anode material, silicon anode has a capacity of up to 4200mAh/g, which is more than 10 times that of graphite anode material, and is the most promising next-generation lithium-ion battery anode material. Under this dazzling halo, the silicon negative electrode also has insurmountable shortcomings, which are mainly due to the serious volume expansion of the silicon negative electrode during the lithium intercalation process. In the fully intercalated state, the silicon negative electrode volume expansion can reach 300%. This will cause pulverization and shedding of material particles, which seriously affects its electrochemical performance. Efforts to reduce the volume expansion of silicon anode materials, such as nanoparticles, thin film electrodes, carbon coating treatment, etc., are all efforts made by people to overcome the expansion of silicon anodes. Volume expansion is bad news for lithium-ion batteries, but let’s think about it from another angle. Is there some special purpose for the huge volume expansion of silicon negative electrodes?

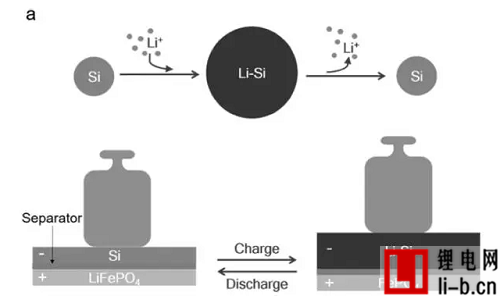

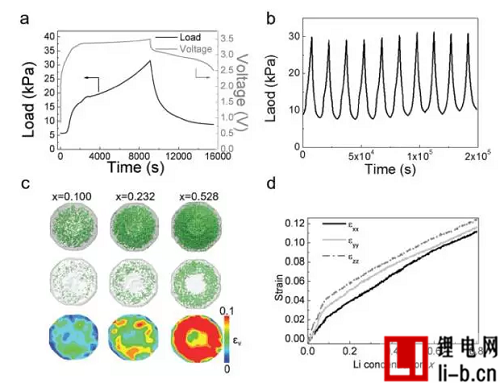

Jialiang Lang and others of Tsinghua University developed a “micro crane” by using the volume expansion of the silicon anode during charging and discharging. The “miniature crane” is actually a soft-pack lithium-ion battery. The positive electrode uses a LiFePO4 material with little volume change, while the negative electrode uses a silicon negative electrode material, and the battery capacity is 2.1Ah. In the experiment, the battery “lifted” 637.5g of water by charging, and the pressure generated by the expansion of the battery in the fully charged state reached 25.8KPa. In the subsequent cycle process An average pressure of 21KPa is generated. Subsequent studies have shown that the battery can generate a maximum pressure of up to 17MPa. During the entire charging and discharging voltage plateau, the battery can continuously generate pressures above 10 MPa. In this process, the energy generated by charging is divided into three parts, one part is converted into mechanical energy, part is converted into chemical energy and stored in the battery, and the other part is converted into thermal energy and dissipated.

Of course, for a device that is intended to convert electrical energy into mechanical energy, the ability to respond quickly is naturally very important. Jialiang Lang has studied the response speed of the volume expansion of the battery in the fast charging and discharging mode. Studies have shown that battery swelling has a good response speed to pulse current. And the expansion distance is basically linear with the charging time. Under the current density of 2A/g, the expansion speed is 1.6nm/s, so this scheme can be used for nanometer-precision positioning. The expansion speed of the battery is mainly related to the surface density of the silicon anode, the thickness of the battery and the current density. Therefore, under the premise of the battery shape, we can control the expansion speed of the battery by controlling the current, so as to achieve the control accuracy we need.

In this study, the capacity of the Si anode is only 800mAh/g, so the “micro crane” still has a lot of room for improvement. The “micro-lifter” can precisely generate nano-scale displacement and can withstand huge loads, so it can be used in some fields that require high-precision positioning at the nano-scale, such as operating scanning tunneling microscope probes. Doing the opposite can often yield good results.