1 High nickel ternary material

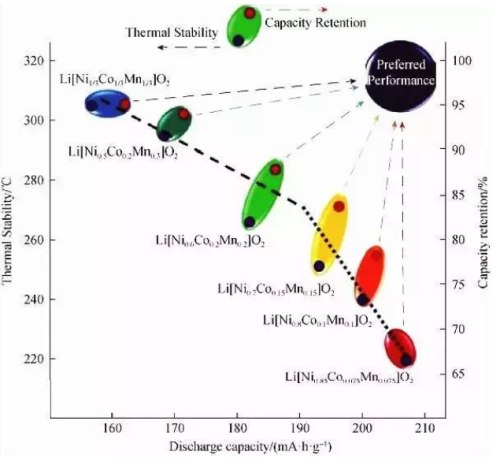

Nickel-cobalt-manganese has the characteristics of high specific capacity, long cycle life, low toxicity, and low cost. In addition, it has a good synergistic effect among the three elements, so it has been widely used. It is used as a cathode material for lithium batteries. In redox energy storage, nickel is the main component. How to effectively improve the specific capacity of the material by increasing the content of nickel in the material is one of the current research hotspots.

Generally speaking, high-nickel ternary cathode material means that the mole fraction of nickel in the material is greater than 0.6. Such ternary material has the characteristics of high specific capacity and low cost, but also has low capacity retention rate, poor thermal stability, etc. defect.

The material properties can be effectively improved through the improvement of the preparation process. The micro-nano size and morphological structure of the particles determine the performance of the high-nickel ternary cathode material to a large extent. Therefore, the main preparation method at present is to uniformly disperse different raw materials and obtain nano-spherical particles with large specific surface area through different growth mechanisms.

Among many preparation methods, the combination of co-precipitation method and high-temperature solid-phase method is the current mainstream method. First, the co-precipitation method is used to obtain a precursor with uniform mixing of raw materials and uniform particle size of the material. A ternary material with an easy-to-control process, which is currently the main method of industrial production.

Compared with the co-precipitation method, the spray-drying method has a simpler process and faster preparation speed, and the morphology of the obtained material is no less than that of the co-precipitation method, which has the potential for further research. The shortcomings of high nickel ternary cathode materials such as cation mixing and phase transition during charge and discharge can be effectively improved by doping modification and coating modification. While suppressing the occurrence of side reactions and stabilizing the structure, improving electrical conductivity, cycle performance, rate performance, storage performance, and high temperature and high pressure performance will remain a research hotspot.

2 Lithium-rich ternary materials

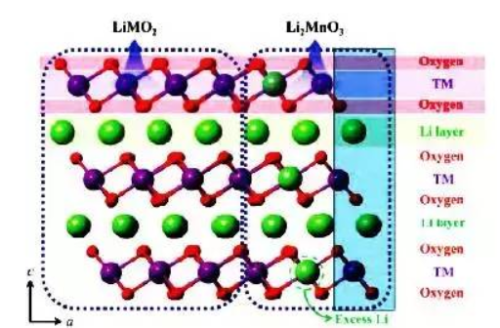

All of this material has the characteristics of high voltage, and the first charge-discharge mechanism is different from the subsequent charge: the first charge will cause a change in structure, which is reflected in the charge curve with two different plateaus demarcated by 4.4V, During the second charging process, the charging curve is different from that of the first charging process. Due to the irreversible release of Li2O from the layered Li2MnO3 during the first charging process, the plateau at around 4.5V disappears.

Lithium-rich ternary cathode materials with different structures can be prepared by solid-phase method, sol-gel method, hydrothermal method, spray pyrolysis method and co-precipitation method. Each method has its own advantages and disadvantages.

Lithium-rich ternary materials show good application prospects and are one of the key materials required for next-generation high-capacity lithium-ion batteries, but research continues for large-scale applications.

The future research directions of this material are mainly in the following aspects:

(1) Insufficient understanding of the mechanism of lithium extraction and intercalation, unable to explain the phenomenon that the coulombic efficiency of materials will be low and the material properties will vary greatly;

(2) The research on doping elements is not sufficient and relatively single;

(3) Poor cycle stability due to the corrosion of the positive electrode material by the electrolyte at high voltage;

(4) There are few commercial applications, and the investigation on safety performance is not comprehensive enough.

3 Single crystal ternary cathode material

At high voltage, as the number of cycles increases, the secondary particles or agglomerated single crystals may be pulverized at the interface of the primary particles or separated from the agglomerated single crystals, resulting in increased internal resistance and increased battery capacity. Fast decay and poor circulation.

The single-crystal high-voltage ternary material can improve the lithium ion transfer efficiency and reduce the side reaction between the material and the electrolyte, thereby improving the cycle performance of the material under high voltage. First, the ternary material precursor was prepared by co-precipitation method, and then single crystal LiNi0.5Co0.2Mn0.3O2 was obtained under the action of high temperature solid phase.

This material has a good layered structure. At 3-4.4 V, the 0.1 discharge specific capacity of the button battery can reach 186.7 mAh/g, and the discharge specific capacity of the full battery after 1300 cycles is still 98% of the initial discharge capacity. %, is a ternary cathode composite material with excellent electrochemical performance.

Xinzheng Lithium Industry adopts a unique preparation process, designs and assembles an advanced lithium-ion battery cathode material production line, and produces micron-sized single crystal particles modified spinel lithium manganate and nickel-cobalt manganese acid on a large scale for the first time in the world. Lithium ternary cathode material, with an annual production capacity of 500 tons.

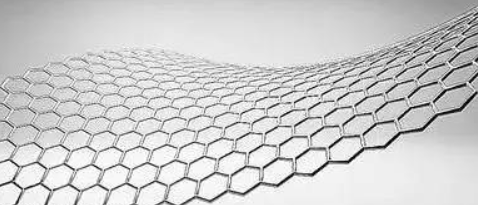

4 Graphene doping

Graphene has a two-dimensional structure with a single-layer atomic thickness, which is structurally stable and has an electrical conductivity of up to 1×106 S/m. The use of graphene in lithium-ion batteries has the following advantages: ① good electrical and thermal conductivity, which helps to improve the rate performance and safety of the battery; ② compared with graphite, graphene has more lithium storage space, which can improve the energy density of the battery; ③ The particle size is in the micro-nano scale, and the diffusion path of lithium ions is short, which is beneficial to improve the power performance of the battery.

JAN’s research group used the grinding method to first mix graphene and 811-type ternary material, then stirred at 50 °C for 8 hours, and then dried to obtain graphene/811 composite material. Due to the modification of graphene, the capacity, cycle stability and rate capability of the cathode material are significantly improved.

WANG adds graphene when preparing ternary precursors by precipitation method. The addition of lamellar structure graphene to its cavity structure reduces the agglomeration of primary particles, relieves the external pressure and reduces the crushing of secondary particles, and the three-dimensional conductivity of graphene The network enhances the high rate capability and cycling performance of the material.