Based on the depth of powder processing technology and the changes in the physicochemical and application characteristics of powder materials, ultrafine powders are generally defined as powdered materials with a particle size of less than 10 μm. With the development of science and technology, many industries and production processes require solid materials in powder form as raw materials. These powders need to have small particle sizes, high purity without impurities, and specific particle size distributions. Therefore, the application of ultrafine powder grinding technology and equipment is becoming increasingly widespread, and researchers are paying more attention to and emphasizing ultrafine grinding technology and equipment.

Air jet milling technology, as an important method for preparing ultrafine powders, has become one of the preferred methods for developing various high-performance micro-powder materials.

Characteristics of Air Jet Mills

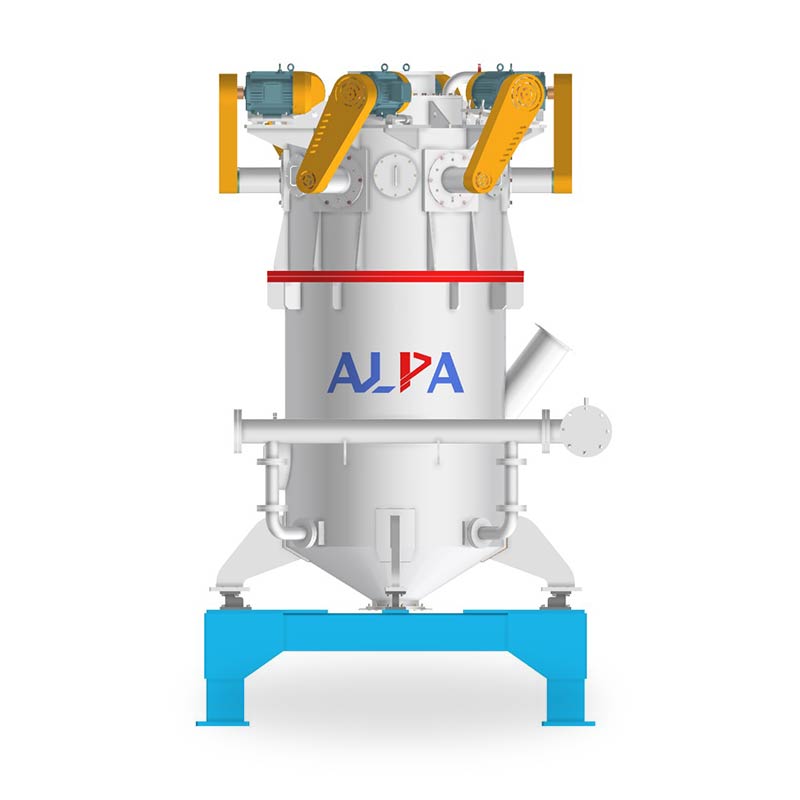

Air jet mills, also known as fluid energy mills, utilize high-speed airflow to cause collisions, impacts, and shearing actions between the material and impact components, resulting in pulverization. The products obtained from air jet milling have uniform fineness, a narrow particle size distribution, high purity, smooth particle surfaces, regular shapes, and good dispersibility.

The material is subjected to minimal contamination during the grinding process, and it can even be carried out in a pollution-free and sterile environment. Therefore, it can be applied to ultrafine grinding in fields such as food and pharmaceuticals, where contamination is unacceptable. Air jet mills do not release a large amount of heat during the grinding process, making them more suitable for grinding low-melting point or heat-sensitive materials compared to other grinding equipment. The production process is highly automated and can be used for large-scale industrial production.

Air jet milling can also combine grinding with subsequent production steps, such as simultaneously achieving material grinding and drying, or spraying solutions during grinding to coat or surface-modify the powder. However, it has disadvantages such as high energy consumption.

Applications of Air Jet Mills

In military and aerospace fields, ultrafine powder materials can be used to manufacture stealth materials for stealth aircraft and tanks. Rocket propellants made from products obtained by air jet milling and refining oxidizers and catalysts have a combustion speed more than double that of ordinary propellants.

In the electronics field, ultrafine iron oxide powder can be used to produce high-performance magnetic materials. Ultrafine silicon dioxide powder can be used to produce high-performance resistive materials. Ultrafine high-purity alumina powder can be used to manufacture sapphire substrates for LED chips. Substrates produced from ultrafine powder have good stability, excellent light transmittance, and do not absorb visible light. After processing with air jet milling technology, molybdenum powder exhibits smaller particle size, narrower particle size distribution, uniform morphology, and improved bulk and tap densities, making it more suitable for the production of light bulbs, electron tubes, and integrated circuits.

In the field of new energy, materials processed by air jet milling have a fine average particle size, a narrow particle size distribution, smooth particle surfaces, regular particle shapes, high purity, high activity, and good dispersibility, meeting the requirements for the preparation of electrode materials, and are therefore widely used. Typical materials suitable for air jet milling include: lithium manganate, lithium cobaltate, lithium iron phosphate, lithium carbonate, spherical graphite, petroleum coke, pitch coke, ternary materials, nickel-metal hydride alloys, ferrous oxalate, lithium titanate, and lithium nickel manganate.

Air jet milling technology is an important technical means for processing micro- and nano-sized powders, and its research can effectively improve resource utilization efficiency.