Artificial graphite has excellent physical and chemical properties such as light weight, high temperature resistance, acid and alkali resistance, self-lubrication, good electrical and thermal conductivity, and is widely used in aerospace, automobile, shipbuilding, chemical industry and other fields. In the field of lithium battery, artificial graphite has the characteristics of high capacity, good cycle and rate performance, strong adaptability to electrolyte, and good safety. Its market share in lithium-ion battery anode materials is also increasing year by year.

1. What is artificial graphite powder?

Artificial graphite products produce a certain amount of chips in the machining process, referred to as artificial graphite powder.

High-end graphite products such as heat exchangers, reaction tanks, filters, piston rings, sealing rings and bearings are mostly machined from high-strength, high-density artificial graphite blanks, but due to the high brittleness and poor machinability of artificial graphite As well as the existence of tool interference, a large amount of artificial graphite dust will be generated by traditional mechanical cutting. Artificial graphite dust is difficult to recycle and reuse, and it will cause dust pollution if not handled properly. Due to the different uses of artificial graphite products, the materials and processes are different, and the physical and chemical properties of the graphite powder produced are also different. The global annual output of various artificial graphite products is about 3 million tons, and about 20%-30% of the waste products due to processing cutting or cracks are converted into artificial graphite powder.

At present, the development and application of artificial graphite powder is mainly used as a raw material for the production of battery anode materials or as an additive to improve the performance of composite materials.

Most of the medium and high-end artificial graphite anode materials are made of petroleum coke and needle coke as raw materials, which are prepared through powder milling, secondary granulation, asphalt coating, carbonization, graphitization and other processes. The production process is long and the manufacturing cost is also high. .

The negative electrode material directly prepared from artificial graphite powder has high specific surface area and low tap density, and is generally used as a low-end negative electrode material.

Studies have found that by mixing artificial graphite powder and hard carbon powder in a mass ratio of 3:7, the composite negative electrode material has the best overall performance and significantly improved low-temperature performance. Some researchers used modified asphalt to coat, pre-oxidize, and carbonize artificial graphite powder, which greatly improved the electrochemical performance of the negative electrode material.

2. Classification and properties of artificial graphite powder

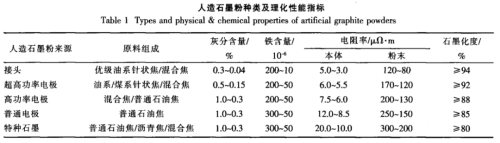

According to the difference of graphite powder aggregate coke, artificial graphite powder can be divided into joint electrode, ultra-high power, high power, ordinary power electrode graphite powder and special graphite product graphite powder.

Compared with GB/T24533–2019 lithium-ion battery graphite anode material quality standard, according to the carbon content of graphite anode material, it can be divided into 4 categories: ≧99.97%, ≧99.95%, ≧99.90%, ≧99.70%. According to the iron content, it can be divided into 5 categories: ≦10×10-6, ≦20×10-6, ≦30×10-6, ≦50×10-6, ≦100×10-6. The higher the carbon content and the lower the iron content, the higher the quality level of graphite-based negative electrode materials. It can be seen from Figure 1 that the joint electrode graphite powder can meet the basic quality requirements of graphite anode materials in terms of performance, while high-power, ordinary graphite electrodes and special graphite powders have low degree of graphitization, low carbon content, and high ash and iron content. There is a large gap in the quality requirements of negative electrode materials.

3. Electrochemical properties of anode materials prepared from artificial graphite powder

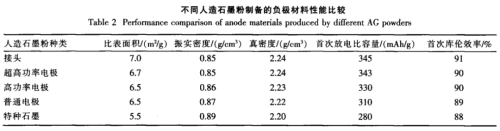

The researchers took the graphite powder from the artificial graphite product processing line separately in a turbo jet mill to pulverize, shape, and spheroidize to prepare a negative electrode material with a particle size of D50 of 18-22 μm. The physicochemical properties of the prepared negative electrode material were tested according to the detection and inspection methods of the national standard GB/F24533-2019 “Graphite Negative Electrode Materials for Lithium Ion Batteries”. After that, a LIR2025 button battery was made, and its electrochemical properties were tested and analyzed. The physicochemical properties and electrochemical properties are shown in Figure 2.

It can be seen that different artificial graphite powders can prepare electrochemically active anode materials, among which the specific capacity and the first coulombic efficiency of the joint graphite powder and the ultra-high power electrode graphite powder anode material are better. Ordinary electrodes and special graphite products have low specific capacity because of their low graphitization degree.

4. Deficiencies and modification of graphite powder to prepare negative electrode materials

Taking the graphite powder of the electrode joint as an example, the researchers analyzed the ash and iron content in the graphite powder of the electrode joint, and the harm of the iron content of the negative electrode material to the battery. Since the surface layer of artificial graphite products adheres to impurities such as graphitization furnace resistance materials, if these impurities are not pretreated, the ash and iron content of graphite powder will increase significantly, which will seriously affect the quality of the prepared negative electrode material. The experimental research shows that the surface cleaning and purification has a very obvious effect on reducing the ash and iron content in the graphite powder.

After the artificial graphite powder is converted into micron-sized particles by high-speed eddy current mechanical crushing and grinding, the surface morphology and microstructure will undergo subtle changes, showing the defects of increased surface scale fragments, increased specific surface area and low tap density. Affect the full play of electrochemical performance. In view of the existing defects, through appropriate process technology modification, graphite powder can be used to prepare medium and high-end anode materials.

In general, the preparation of anode materials from artificial graphite powder is a green, environmentally friendly and energy-saving anode material production scheme, which is worthy of research and promotion. By strengthening the research on the application of artificial graphite powder to anode materials, it is believed that there will be a good room for improvement in this field in the future.