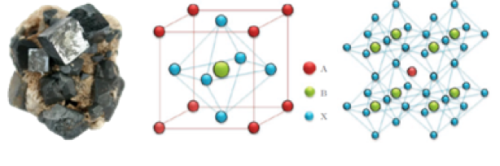

Perovskite is a symmetrical cuboctahedral lattice structure, and scientists later referred to a class of substances with this lattice structure as perovskites. Such materials usually have the chemical formula of ABX3, where A, B, and X correspond to different ions. Usually, A represents an organic amine cation, B represents a metal cation, such as lead Pb ion, tin Sn ion, and X represents a halogen anion. Therefore, perovskite does not refer to a specific material, but a structure, a class of substances.

Figure 1: Crystal structure and A, B, X ions of perovskite

Perovskite solar cells (PSCs) are the representative of the third-generation high-efficiency thin-film cells, which have the potential for high efficiency, high flexibility, and low cost, and are known as “new hope in the photovoltaic field”. Perovskite cells can also further improve the photoelectric conversion efficiency by stacking with HJT, which is the key research direction of future industrialization.

The main problems in the process of industrialization of perovskite solar cells are to solve the problems of stability, large-scale preparation and environmental protection.

The main advantages of perovskite cells are: high efficiency, low cost advantage, and consumption reduction.

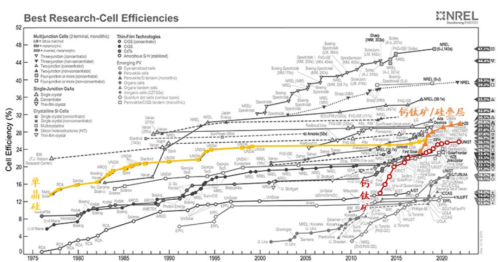

The photoelectric conversion efficiency of perovskite is obviously improved rapidly, and the slope in the figure below is very large. Perovskite has increased from 3.8% to 25.7% in about 10 years.

The theoretical conversion efficiency of single-junction perovskite cells can reach 31%. Single-junction means only one PN junction, and multi-junction means has multiple PN junctions. Multi-junction has better spectral absorption effect and higher efficiency, but the cost is also higher. The maximum photoelectric conversion efficiency of multi-junction perovskite can reach 47%, which is indeed high compared to the theoretical maximum efficiency of 29.4% for crystalline silicon cells.

TOPCon and HJT are the new generation technologies of crystalline silicon cells leading PERC cells. Although the current mainstream technology in the market is still PERC, the current capacity expansion is mainly concentrated in TOPCon and HJT. With the maturity of TOPCon and HJT, crystalline silicon-perovskite tandem cells have also become the focus of research and development.

It should be said here that compared with TOPCon, perovskite and HJT have better tandem battery matching. According to the forbidden band width from small to large and the spectral band from long to short, different materials can be listed from bottom to top in turn to form a tandem battery. With a narrow bandgap of 1.1eV, HJTs are very suitable as bottom cells, and the matching top cells have a bandgap between 1.6-1.9eV. By adjusting the elemental composition of perovskite, a tunable forbidden band width from 1.5-2.2 eV can be obtained. When the band gap is adjusted to a suitable band gap, a high-efficiency tandem battery can be formed.

Perovskite-HJT tandem cells can more reasonably utilize photons in the full spectral range and reduce energy loss. It is an important method to break through the efficiency limit of single-junction cells. Current research shows that the limit efficiency is 44-45%, which is higher than that of HJT cells. There is a big improvement.

At present, the efficiency of large-area components of perovskite is still much lower than that of small-area components, and many ultra-recorded efficiencies in the laboratory are small components. The main reasons for the significant efficiency gap between small area and large area are:

1. It is more difficult to control the coverage, uniformity and flatness of large-area films under the solution treatment method;

2. The increase of defects in the perovskite layer has a negative impact on the extraction and transport of light-induced carriers;

3. The resistance of the transparent electrode increases approximately linearly with the increase of the area, which increases the series resistance of the battery and reduces the performance.

At the same time, perovskite has the risk of environmental pollution, which is also a problem to be solved in industrialization. Perovskite batteries contain lead, which is listed as a prohibited material in many countries and regions around the world. Researchers are working hard to explore lead-free perovskites, but the conversion efficiency will be reduced accordingly.