The research group of Gregory Offer of Imperial College London, the research group of Academician Ouyang Minggao of Tsinghua University and Billy Wu of Faraday Institute and researchers of Shell Oil Company jointly published a review on fast charging of lithium-ion batteries in the international transportation electrification journal eTransportation Article (Lithium-ion battery fast charging: A review). This article comprehensively reviews the factors affecting the fast charging of lithium-ion batteries, the main problems and solutions of fast charging from the material level to the system level.

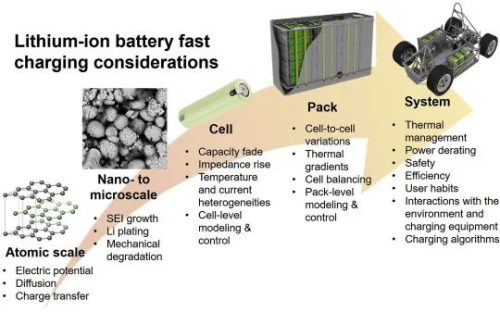

The widespread adoption of lithium-ion batteries in pure electric vehicles has accelerated in recent years to limit the impact of climate change and air pollution. However, compared with traditional fuel vehicles, problems such as mileage anxiety and long charging time have become the main problems hindering the development of electric vehicles. Therefore, the improvement of fast charging capability has become a common development goal of battery manufacturers and OEMs. However, studies have shown that low-temperature and high-rate charging will cause accelerated degradation of battery capacity and output power; question. Figure 1 shows the factors that affect the fast charging of lithium-ion batteries from the atomic level to the automotive system level. This paper focuses on the review and summary of the existing literature, and analyzes the key technical constraints at each level.

The classification of electric vehicle charging includes AC and DC, with DC charging faster. Tesla is the first company to use 120kW fast charging; Bosch released a 350kW fast charging plan in 2017, which was implemented in “Taycan” in 2019. Since the voltage of the current vehicle battery pack is around 400V, the high-power charging of 350kW requires a higher voltage of the pack to avoid the problems of excessive current and excessive heat generation. Both the Bosch “Taycan” and Audi’s e-tron GT concept car (with a charging power of 350kW) are equipped with an 800V lithium-ion battery pack. In December 2018, a joint research group from BMW, Bosch and Siemens achieved fast charging in 450kW CCS mode on two test cars in Germany.

Although there has been great progress in the research on improving the charging power of electric vehicles, these fast charging technologies are not suitable for all situations. According to the specific working conditions and charging environment of the electric vehicle, the charging power will gradually decay during the continuous charging process. In addition, in the fast charge mode, due to safety and other factors, the battery can usually only be charged to 80% of the power; when the power is higher, the charging rate will gradually decrease to avoid overcharging. In addition, the charging power is also limited by the battery management system (BMS). With the growing interest in the field of fast battery charging, it is necessary to understand the speed-determining steps of different charging methods and their impact on battery life. This paper aims to establish linkages between microscopic processes, material properties, battery and pack design, and charging strategy optimization, starting from the multiscale and multidisciplinary nature of fast charging.

The principle of fast battery charging

The ideal battery should exhibit long life, high energy density and high power density to be able to charge and recharge quickly in any location and at any temperature to meet the long-distance driving requirements of electric vehicles. However, there is a trade-off relationship between these physical properties, and the influence of material and device temperature determines the battery usage threshold. As the temperature drops, both the charge rate and the maximum voltage should be reduced for safety, making temperature a key limiting factor for fast charging. Among them, as the temperature decreases, the risk of lithium precipitation increases significantly. Although many researchers have pointed out that lithium precipitation often occurs at temperatures below 25 °C, it is also prone to occur at high temperatures, especially when the charging rate is high and the energy density is high. In addition, the relationship between fast charging efficiency and temperature is also very close. The charging efficiency of a 50kW charging pile at 25°C is 93%, but the charging efficiency at -25°C is as low as 39%. This is mainly because the BMS will limit the rating at low temperatures. power.

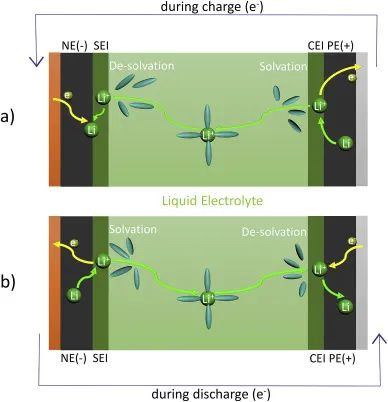

A common lithium-ion battery is mainly composed of a graphite negative electrode, a lithium metal oxide positive electrode, an electrolyte, a current collector, and a porous separator. As shown in Figure 2, Li+ is transported from the positive electrode to the negative electrode through the electrolyte during charging. The main transport paths are: 1) through the solid electrode; 2) through the electrode/electrolyte interface of the positive and negative electrodes; 3) through the electrolyte, including Solvation and desolvation of Li+. However, improper use conditions of batteries often cause a series of side reactions that affect performance and life. In addition, the charge-discharge rate, battery internal resistance and battery polarization will affect the thermal characteristics of the battery, such as increasing heat generation, reducing charging efficiency and safety, etc.

Numerous studies have shown that the decay of the positive electrode and the growth of the positive CEI film have no effect on the fast charging speed of conventional Li-ion systems, so the negative electrode becomes the main concern during the charging process. Under certain circumstances, lithium metal may continue to precipitate into lithium dendrites, and even pierce the separator to cause an internal short circuit. Factors affecting Li deposition and deposition structure include the diffusion rate of Li ions in the anode, the electrolyte concentration gradient at the anode interface, the metal salt deposition of the current collector, and the side reactions at the electrode/electrolyte interface. The research shows that the performance of the negative electrode during lithium deposition can be attributed to the influence of the current at the beginning of the lithium deposition on the internal resistance of the negative electrode surface density. Reducing the internal resistance of the negative electrode through battery design is very important to improve the fast charging capability of the battery. In addition, the effect of temperature is also very important. Too low or too high temperature will be considered unfavorable to the battery, but the higher temperature of the battery during fast charging will help its own balance, especially for high specific energy batteries. The effect of electrode thickness on charging performance also needs attention. Thin electrodes are often considered for ideal lithium ion transport, and as the electrode thickens, it becomes important to ensure sufficient lithium ion concentration at the electrode/electrolyte interface to maintain overpotential stability and reduce the possibility of lithium evolution. During fast charging of thick-electrode batteries, lithium salts may be deposited at the current collector, resulting in an imbalance in electrode utilization and an increase in the current density of the separator anode.

The electrification of transportation is undoubtedly one of the important means to address climate change. In order to cope with mileage anxiety and meet customer demands, many manufacturers take the Pack’s fast charging capability as an important indicator. Although there have been many researches on fast charging over the years, there are still many problems:

1. To date, there is still no reliable on-board method to detect battery aging (such as lithium deposition and mechanical cracking). The detection method of lithium precipitation based on voltage platform is expected to realize online application, but there is no relevant research on how to effectively distinguish lithium dissolution platform from other phenomena, and to detect lithium precipitation without voltage platform.

2. Many new electrode materials have good fast charging ability, but their stability, attenuation mechanism, large-scale production and cost remain to be discussed. Although graphite anodes are very easy to precipitate lithium, considering the cost, wide application and technological maturity, graphite will occupy the main market for lithium-ion battery anode materials in the foreseeable future.

3. Existing model approaches have obvious limitations: ECM-based models cannot predict the internal state of the battery and can only be used in a limited range. On the other hand, high-precision FOM models cannot be applied in real-time due to the large amount of computation. Therefore, a reduced-order model is needed to accurately describe the internal core state of the battery for application in future fast-charging BMS systems.

4. Many fast charging strategies are developed based on experience or experiments, and the results are only applicable to batteries with specific configurations or specific operating conditions, and cannot be extended to other types of batteries. In addition, many model-based charging optimization studies are based on SP or ECM models, and the model prediction accuracy is often insufficient under high current.

5. There are currently few researches on strategies for fast charging optimization at low temperature, and these researches are crucial for the promotion and application of electric vehicles in cold regions.

6. In order to further optimize the charging process of the single cells in the battery pack and avoid local aging or overcharging, it is also necessary to develop an advanced BMS system with balanced battery consistency.

7. Although much research has been devoted to the design of thermal management systems, the efficiency and uniformity of various preheating and cooling systems needs to be further evaluated. Few researchers have evaluated the effect of AC preheating coupled with fast charging on battery life. Optimizing tab design, cooling system location and geometry is also an important means of improving temperature and current uniformity. External cooling technology coupled with charging piles is also an important method to reduce the cost and quality of on-board cooling systems, but its real effect remains to be seen.

8. Finally, the relationship between the decay rate of the battery cell and the pack is not clear. Although many charging and preheating strategies are effective in battery cells, the effect, feasibility and cost of their application in Pack are still lacking. The application of some effective charging strategies for single cells to the pack may cause uneven temperature and current density distribution, so any non-traditional charging technology needs a lot of research before practical application. Furthermore, few models take into account the effects of cell-to-cell inconsistencies within the battery pack. Since fast charging will magnify inconsistencies, multi-scale research needs to be carried out urgently. Multi-scale research is crucial for cell integration and pack design of batteries.