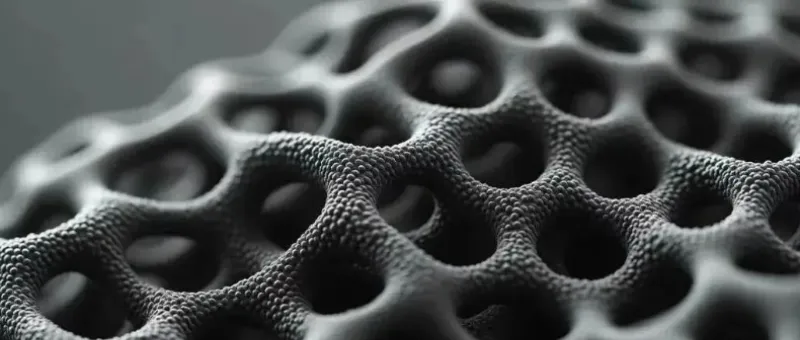

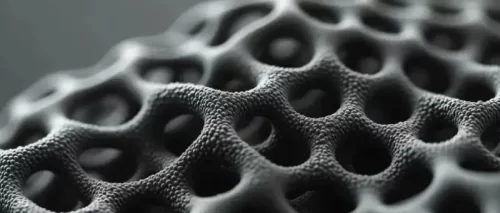

Porous carbon materials are carbonaceous materials with a rich pore structure (including micropores, mesopores, and macropores). Their high specific surface area, excellent conductivity, and chemical stability make them ideal electrode materials. In battery applications, porous carbon provides more active sites for the insertion and extraction of lithium ions. Furthermore, its porous structure mitigates the volume change of the electrode material during charge and discharge, thereby improving the battery’s cycle life.

Traditional porous carbon materials are primarily derived from biomass (such as coconut shells and wood) or fossil fuels. However, the source and quality of these raw materials are often unstable, resulting in poor product performance consistency. Resin-based porous carbon, on the other hand, uses synthetic resins or biomass-derived resins as precursors and is prepared through precisely controlled carbonization and activation processes. It offers advantages such as controllable structure and high purity.

Classification and Characteristics of Resin-Based Porous Carbon

Depending on the source of the precursor, resin-based porous carbon can be divided into several categories:

1. Synthetic Resin-Based Porous Carbon

Phenolic resin is currently the most popular synthetic resin-based porous carbon precursor. Its raw materials are readily available, and the process is relatively mature. It is typically prepared through solution polymerization, curing, carbonization, and activation. Phenolic resin-based porous carbon can be fabricated into perfectly spherical, quasi-spherical, or blocky irregular shapes. Its pore structure (micropore/mesopore ratio) is highly controllable, and it offers high mechanical strength, excellent anti-swelling, and excellent pressure resistance.

These properties are crucial for silicon-carbon anode materials, as silicon undergoes significant volume expansion (approximately 300%) during charge and discharge. The rigid skeleton of resin-based porous carbon effectively suppresses this expansion, improving electrode stability. Research has shown that phenolic resin-based porous carbon, as a support for silicon deposition, achieves highly uniform and consistent silane deposition, resulting in a first-pass coulombic efficiency exceeding 88% and significantly extending the cycle life of silicon-carbon anodes.

2. Biomass-derived resin-based porous carbon

This is an emerging green approach, using biomass refinery products (such as lignin derivatives and sugar derivatives) as raw materials to synthesize resins, which are then carbonized to produce porous carbon. This method combines the structural stability of traditional resin-based materials with the low cost of biomass carbon. Shengquan New Energy’s development of this type of product using its biomass refining intermediates is a typical example of this technology. Biomass-derived resin-based porous carbon is not only more cost-effective but also aligns with the concept of sustainable development and has broad application prospects.

Preparation Process for Composite Porous Carbon Materials

A company’s patent demonstrates a method for preparing composite porous carbon materials that combines the advantages of multiple technologies. The key to preparing resin-based porous carbon lies in the selection of polymer precursors, molding, curing (cross-linking), carbonization, and activation. These process details directly impact the structure, performance, and cost of the final product.

1. Precursor Synthesis

To synthesize resin-based porous carbon, phenolic resin is typically synthesized through the polycondensation reaction of phenol and formaldehyde. Biomass-derived resins, on the other hand, utilize biomass refining technology to convert depolymerization products such as lignin and cellulose into cross-linkable resin intermediates.

2. Molding and Spheronization

Spherical porous carbon materials are favored by researchers due to their high tap density and excellent electrode processing properties. Spray drying is a classic method for preparing micron-sized particles, offering advantages such as simplicity, low cost, and scalability. During the spray drying process, nanosilicon powder, a carbon source (such as sucrose), a carbon nanotube dispersion, and a CMC aqueous solution are mixed in a specific proportion and treated with ultrasound and stirring to ensure uniform dispersion. The mixture is then dried into precursor microspheres using a spray dryer. Spray drying conditions (such as temperature, spray volume, and atomization pressure) require precise control to obtain microspheres with the desired morphology and structure.