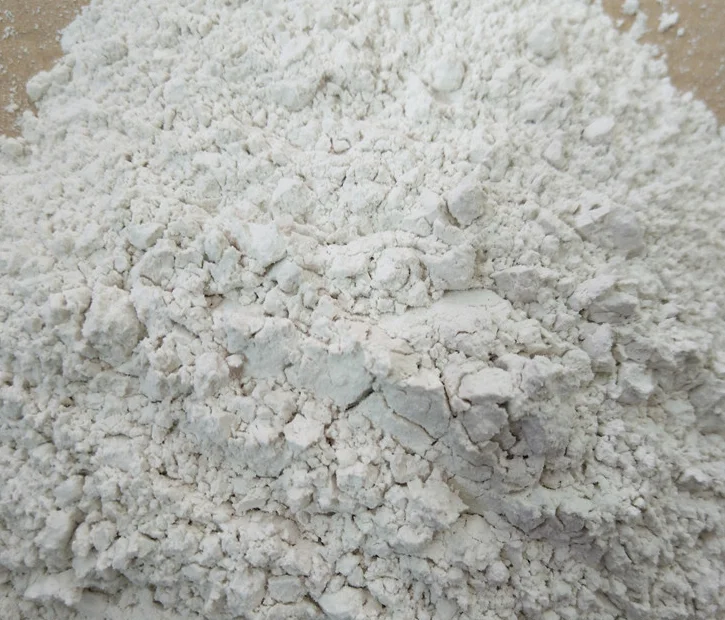

However, the whiteness of raw tourmaline ore is very low, which seriously restricts its application in the fields of building materials and environmental materials. Therefore, it is of great significance to improve its whiteness without affecting its negative ion release.

A research team has developed a method for preparing high-whiteness negative ion powder. This preparation method can convert low-whiteness tourmaline into high-whiteness, efficient negative-ion release, and non-radiation negative-ion powder, thereby improving the utilization value of tourmaline.

The preparation method includes the following steps:

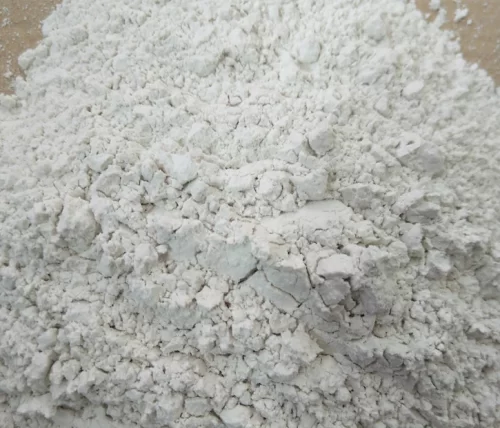

(1) Ball-grind the tourmaline raw ore into tourmaline powder, mix the tourmaline powder, dispersant and water in a mass ratio of 1: (0.01~0.1): (0.8~1.5), and add an average particle size of 0.2mm~ 0.4mm grinding media, the mass ratio of the grinding media to tourmaline powder is (3~10):1, the grinding time is 150min~300min, and the grinding speed is 2000~3000 rpm;

(2) Add a surface modifier to the system. The mass ratio of the surface modifier to the tourmaline powder is (1~8):1. Continue grinding for 1~2 hours at a grinding speed of 2000~3000 rpm. After the reaction is completed, a high-whiteness negative ion powder slurry is obtained, and the high-whiteness negative ion powder is obtained by drying. The test results are that the whiteness is 65.63 and the negative oxygen ion release value is 779.