Guide: Lithium batteries will fail with a certain probability during use or storage, including capacity attenuation (diving), short cycle life, increased internal resistance, abnormal voltage, lithium precipitation, gas production, liquid leakage, short circuit, deformation, heat Out of control, etc., seriously reduce the performance, consistency, reliability and safety of lithium batteries. Accurately diagnosing lithium battery failure and exploring its failure mechanism is the main task of lithium battery failure analysis, and it also has far-reaching significance for lithium battery performance improvement and technological development.

Introduction to Failure Analysis of Lithium Batteries

The national standard GB3187-82 defines: “Failure (failure) – the product loses its specified function. For repairable products, it is usually called a failure.” The failure of lithium batteries refers to the deterioration of battery performance due to some specific essential reasons. Or use performance exceptions. The failures of lithium batteries are mainly divided into two categories: one is performance failure, and the other is safety failure, as shown in Figure 1. Performance failure refers to that the performance of lithium batteries does not meet the requirements and related indicators, mainly including capacity attenuation or diving, short cycle life, poor rate performance, poor consistency, easy self-discharge, high and low temperature performance degradation, etc.; safety failure refers to The main problem is that due to improper use or abuse of lithium batteries, failures with certain safety risks occur, mainly including thermal runaway, flatulence, liquid leakage, lithium precipitation, short circuit, expansion deformation, etc.

Classification of common lithium battery failures

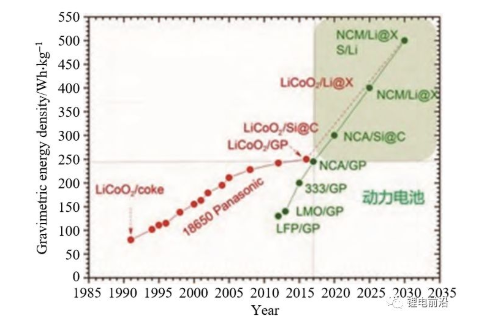

The birth of failure analysis is accompanied by failure phenomena, and its purpose is to determine and prevent its occurrence. Failure analysis is a technical and management activity for judging product failure modes, analyzing failure causes, and predicting or preventing failure phenomena. People have put forward higher requirements for the performance indicators of lithium batteries, especially in terms of volume/mass energy density, power density, cycle life, cost, safety performance, etc. For example, energy-based lithium batteries are mentioned in “Made in China 2025” The specific energy of the battery is greater than 300 W·h/kg, and the specific power of the power lithium battery is greater than 4000 W/kg. Figure shows the development roadmap of lithium-ion battery energy density from 1990 to 2025. In order to meet the needs of the market, improve the performance and safety of batteries, and shorten the development cycle of new systems, it is necessary to carry out failure analysis of lithium batteries.

Although the birth of a product is accompanied by failure, the failure is recognized by people as starting from the failure phenomenon, so the failure analysis work should start from the failure phenomenon. First of all, we should start with the failure phenomenon of lithium battery. The failure phenomenon of lithium battery is the first step of failure analysis of lithium battery, and it is one of the most direct and important failure information. If the failure information of lithium battery is not fully grasped and analyzed, the root cause of failure of lithium battery cannot be accurately obtained, so it is not only impossible to provide constructive suggestions or reliability assessment. The failure phenomenon is divided into two parts: dominant and recessive. Dominant refers to directly observable manifestations and characteristics, such as fracture and deformation of the surface structure that occur at the failure site and can be observed by macroscopic analysis, including fire burning, heating, bulging (gas production), deformation, leakage, encapsulation Material damage and distortion, packaging material burrs, virtual welding or missing welding, melting and deformation of plastic materials, etc. Recessive refers to the performance and characteristics that cannot be directly observed but need to be obtained after disassembly, analysis or simulated experiments, such as microscopic failures detected by laboratory disassembly, and electrical information in simulated batteries, etc. In the process of lithium battery failure, there are often hidden failure phenomena such as short circuit in the positive and negative electrodes, lithium precipitation, powder drop of the pole piece, diaphragm aging, diaphragm blockage, diaphragm puncture, electrolyte drying, electrolyte denaturation failure, negative electrode dissolution, transition metal Precipitation (including copper precipitation), pole piece burr, abnormal winding (or lamination), capacity diving, abnormal voltage, high resistance, abnormal cycle life, abnormal high/low temperature performance, etc. The scope of the failure phenomenon often intersects with the scope of the failure mode, and the failure phenomenon is more inclined to the direct description of the phenomenon, which belongs to the information collection and description of the failure process; the failure mode is generally understood as the nature and type of failure, which is the attribute of failure Classes and divisions. Lithium battery failure phenomenon is a large cluster of battery failure performance, and it is necessary to define and classify it.

Failure is the final manifestation of the failure cause, and it is also the result of the superimposed failure phenomenon of the failure cause within a certain period of time. One of the important tasks of failure analysis is to accurately determine the cause of failure. Common causes of lithium battery failure include structural changes of active materials, phase transitions of active materials, cracks or breakage of active particles, dissolution of transition metals, volume expansion, solid electrolyte interface (SEI) overgrowth, SEI decomposition, lithium dendrite growth, electrolysis Liquid decomposition or failure, insufficient electrolyte, mismatch of electrolyte additives, corrosion or dissolution of current collector, failure of conductive agent, failure of binder, failure of diaphragm aging, blocking of diaphragm pores, segregation of pole pieces, material agglomeration, abnormal cell design , abnormal cell aging process, etc. Figure 3 shows the internal failure of a lithium battery. From the research content of the failure reasons of lithium batteries, it can be divided into external causes and internal causes. Among them, external factors include impact, acupuncture, corrosion, high temperature combustion, man-made damage and other external factors; while internal factors mainly refer to the nature of physical and chemical changes in failure, the research scale can be traced back to the atomic and molecular scale, and the thermodynamics and dynamics of the failure process are studied Changes in science. The failure of lithium batteries comes down to the failure of materials. The failure of materials mainly refers to the abnormal occurrence of material structure, properties, and morphology and the mismatch between materials. For example, the particle crushing of the positive electrode material due to the uneven stress of the material due to the inconsistent local Li+ deintercalation rate, the crushing and pulverization of the silicon negative electrode material due to the volume expansion and contraction during the charging and discharging process, the electrolyte is affected by the humidity and temperature. Decomposition or deterioration occurs, the solvent co-insertion problem occurs between the graphite negative electrode and the additive propylene carbonate (PC) in the electrolyte, and the N/P (the ratio of the capacity of the negative electrode sheet to the capacity of the positive electrode sheet) is too small to cause lithium precipitation.

The failure causes of lithium batteries do not always correspond to failures one-to-one, and there are “one-to-many”, “many-to-one” and “many-to-many” relationships. A certain failure cause may have different manifestations in the time span. For example, the abnormal charging and discharging system leads to high current charging and discharging, which may show a large polarization at the beginning, and an internal short circuit due to the precipitation of lithium dendrites in the intermediate stage. With the decomposition and regeneration of Li dendrites, thermal runaway may eventually occur. A variety of completely different failures may occur for a certain failure cause, such as the precipitation of local transition metals, which may generate gas, resulting in a bulging failure performance, but it may also cause local heating due to internal short circuits, which will cause the diaphragm to shrink and cause a large area. of thermal runaway. A certain failure phenomenon may correspond to a variety of failure reasons, such as the failure mechanism of capacity fading, such as material structure change, microstructure damage, contact failure between materials, electrolyte failure or decomposition, conductive additive failure and so on.

Internal failure of lithium battery

Failure analysis is divided into two directions: one is the diagnosis analysis based on the failure of lithium batteries, which starts from the failure and traces the failure mechanism of the battery material to achieve the purpose of analyzing the failure cause; the second is based on the cumulative failure cause database. The mechanism exploration and analysis is based on the failure point of the design material, and explores various factors affecting the failure process of lithium batteries, in order to achieve the purpose of prevention.

The diagnosis and analysis of the lithium battery starts from the failure of the lithium battery. According to the failure performance of the battery, the battery appearance inspection, the battery nondestructive inspection, the battery damage inspection and the comprehensive analysis are carried out. In the face of actual cases, it is necessary to adjust and optimize the analysis process and test items according to different situations. Taking the failure analysis of capacity-fading batteries as an example (as shown in Figure 4), the failure behavior is refined based on the failure performance and service conditions, and the corresponding analysis focus is provided. Such as normal cycle decay, the later analysis focuses on the material structure changes, SEI overgrowth and lithium precipitation and other factors. Through the visual inspection of the failed battery, it is determined whether there are external structural changes or leakage of electrolyte and other factors. Non-destructive testing mainly includes micron X-ray cross-sectional scanning (XCT) and full-cell electrochemical testing. Through the conclusion of non-destructive testing analysis, further confirm the internal structure changes, quantify the failure behavior, select test items, and adjust the analysis process. For example, comparing the charge-discharge curve analysis of a certain LiFePO4/C failed battery and a fresh battery in Figure 5 shows that the discharge capacity has decreased by 21%, and the charge-discharge curve is further processed to obtain a capacity increment (IC) curve. The high potential shift indicates that there is an increase in the difficulty of lithium deintercalation caused by the change of material structure. Combined with the more obvious peak intensity changes at 3.27 V and 3.32 V, it shows that the capacity decline of the battery is mainly due to the loss of active lithium source and the destruction of active material structure, and This further supports the focus of the analysis. The so-called battery destructive testing refers to determining the role of positive and negative electrodes, active materials and separators in battery failure through battery disassembly, electrode observation and material testing and analysis. The testing and analysis of materials is based on physical and chemical properties and electrical The chemical performance test is mainly used. For example, the scanning electron microscope (SEM) morphology test results of the above-mentioned LiFePO4/C failed battery pole piece show that the positive electrode material has obvious structural damage. ◦ The increase of peak intensity reveals the increase of Fex(POy) phase, that is, the phase transition phenomenon exists in the cathode material (as shown in Fig. 6). The X-ray photoelectron spectroscopy (XPS) analysis of the pole piece surface and the half-cell test of the pole piece can qualitatively and quantitatively analyze the SEI and capacity loss of the pole piece surface. Finally, the qualitative or quantitative failure reasons are concluded and an analysis report is provided. The research on the failure mechanism of lithium batteries is to accurately simulate and analyze the complex physical and chemical reaction processes inside the battery through a large number of basic scientific research, as well as the construction of reasonable models and verification experiments, to find out the essential cause of battery failure, and to build a failure cause database. The battery mechanism analysis may be carried out from different angles, including the design material angle and the design failure angle.