The potential of graphite anode is fully tapped

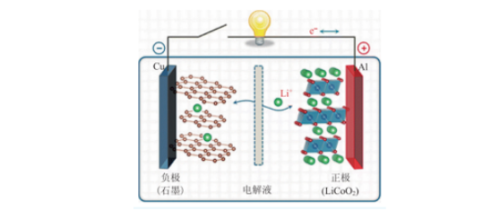

The energy density of the cell is positively correlated with the gram capacity of the negative electrode material. At present, the gram capacity of high-end graphite has reached 360-365mAh/g, which is close to the theoretical gram capacity of 372mAh/g. Therefore, from the perspective of anode materials, the improvement of cell energy density requires the development of anode materials with higher gram capacity.

Silicon-based anode materials have the most commercial prospects

In the silicon-based anode material, Si and Li+ undergo an alloying reaction, and the highest gram capacity can reach 4200 mAh/g, which is more than 10 times that of graphite. In addition, silicon also has the advantages of low electrochemical lithium intercalation potential (about 0.4 V vs. Li/Li+), no lithium precipitation problem, and abundant reserves. It is a very potential anode material for next-generation high-energy density lithium-ion batteries.

Key points of industrialization of silicon-based anode materials: drastic volume change and unstable SEI film

During the charging and discharging process, the formation and decomposition of the silicon-lithium alloy is accompanied by a huge volume change, and the maximum expansion can reach 320%, while the carbon material is only 16%. The drastic volume change leads to the following challenges: the cracking and pulverization of silicon particles, the detachment of the anode active material from the electrode sheet, and the continuous formation of the solid-phase electrolyte layer (SEI film) due to pulverization and detachment. At present, it is mainly through material design (nanometerization of silicon, carbon coating of silicon, addition of silicon oxide, etc.) and battery system optimization (electrolyte additives such as FEC and VC, negative electrode material binders CMC-SBR and polyacrylic acid) Lithium, etc., optimization of conductive agents), etc.

Carbon-coated silicon oxide and nano-silicon carbon have a high degree of commercialization

There are many preparation methods for silicon-based anode materials, and the preparation process is more complicated than that of graphite, and the products have not yet reached standardization. At present, carbon-coated silicon oxide and nano-silicon carbon are the two most commercialized silicon-based anode materials. Mass-producing companies include Betri, Tianmu Pilot, Shanshan, etc. in China, and Shin-Etsu Chemical, Osaka Titanium, Hitachi Chemical, Showa Denko, and Dazhou in Korea are overseas.

The industrialization time of silicon-based anode materials is short; the international Japanese companies are leading, and the domestic Bettray is leading

Japan’s Hitachi, Yuasa and other companies have successively applied silicon-based anodes to consumer batteries and power batteries since 2015, promoting the industrial application of silicon-based anode materials. Domestically, according to Gaogong Lithium’s research, there are no more than 3 companies that can mass-produce silicon-based anode materials. Among them, Betray is a leader in China. It achieved mass production and shipment in 2017, and has successfully entered Panasonic-Tesla. supply chain.

Investment Advice

The beneficiary companies include Betray, a leader in anode materials and a leader in the field of silicon-based anodes, Shanshan Co., Ltd., which started the industrialization of silicon-based anodes, a leader in artificial graphite, and Putailai, which promotes the industrialization of silicon-based anodes.

Risk warning: the impact of the epidemic on the demand for new energy vehicles, the industrial application of silicon-based anodes is less than expected