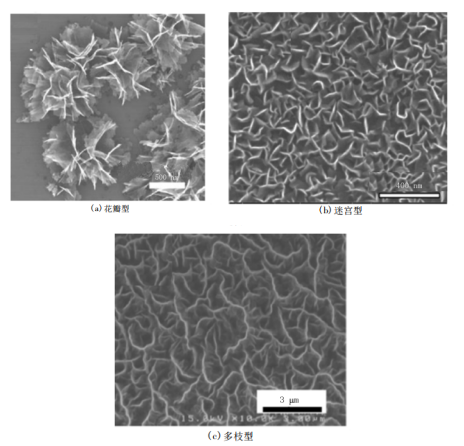

Vertical graphene, also known as vertical carbon nanosheets, is a graphene material with through-channels and abundant edges formed by a graphene sheet structure consisting of multiple layers of graphene standing vertically on a substrate. Its three-dimensional structure is composed of graphene sheets grown vertically to the substrate, which can be regarded as planar graphene with expanded interlayer spacing, and has the same excellent chemical stability and mechanical strength. According to the different morphology, vertical graphene can be divided into petal type, labyrinth type and multi-branch type. Due to its special growth orientation, the number of stacked layers of graphene sheets is reduced. Studies have shown that: if the graphene sheet is thinner, the electron transfer rate is faster, and the single-layer graphene sheet can exhibit excellent metal conductivity. In addition, the introduction of heteroatoms to change its electronic density of states can also improve its electrical conductivity.

As a typical orientation material, compared with traditional horizontal graphene, vertical graphene has the following obvious advantages in morphology and structure:

(1) Vertically oriented growth avoids the interlayer stacking of the horizontal structure and improves the utilization rate of the specific surface area;

(2) The exposed edges provide chemical modification sites, and also have extremely high electrical conductivity and electrochemical activity;

(3) The vertical network structure forms the transmission channel, which is beneficial to the diffusion of ions in the channel and the transfer of electrons in the graphene sheet.

This enables vertical graphene to exhibit excellent performance in various energy and environmental applications, such as supercapacitors, sensors, and solar thermal conversion.

The synthesis methods of vertical graphene mainly include plasma enhanced chemical vapor deposition method, chemical vapor deposition method, radio frequency sputtering method and arc discharge method. Among them, plasma-enhanced chemical vapor deposition technology is a common preparation method for preparing vertical graphene. Generally, hydrocarbon substances (such as methane, acetylene, etc.) are used as carbon sources, and then auxiliary gases (such as hydrogen, argon, water vapor, etc.) are introduced. Under the action of plasma, through the processes of excitation, ionization, collision, etc., A variety of active groups are generated, and finally grow vertically on the substrate after the process of nucleation and etching. This method can quickly and efficiently prepare vertical graphene in one step, and does not require a binder, which solves the problem of the decrease in conductivity caused by adding a binder during the preparation of horizontal graphene electrodes.

As a typical orientation material, compared with traditional horizontal graphene, vertical graphene has the following obvious advantages in morphology and structure:

(1) Vertically oriented growth avoids the interlayer stacking of the horizontal structure and improves the utilization rate of the specific surface area;

(2) The exposed edges provide chemical modification sites, and also have extremely high electrical conductivity and electrochemical activity;

(3) The vertical network structure forms the transmission channel, which is beneficial to the diffusion of ions in the channel and the transfer of electrons in the graphene sheet.

This enables vertical graphene to exhibit excellent performance in various energy and environmental applications, such as supercapacitors, sensors, and solar thermal conversion.

The synthesis methods of vertical graphene mainly include plasma enhanced chemical vapor deposition method, chemical vapor deposition method, radio frequency sputtering method and arc discharge method. Among them, plasma-enhanced chemical vapor deposition technology is a common preparation method for preparing vertical graphene. Generally, hydrocarbon substances (such as methane, acetylene, etc.) are used as carbon sources, and then auxiliary gases (such as hydrogen, argon, water vapor, etc.) are introduced. Under the action of plasma, through the processes of excitation, ionization, collision, etc., A variety of active groups are generated, and finally grow vertically on the substrate after the process of nucleation and etching. This method can quickly and efficiently prepare vertical graphene in one step, and does not require a binder, which solves the problem of the decrease in conductivity caused by adding a binder during the preparation of horizontal graphene electrodes.