Overcharging is one of the most difficult items to pass in the current lithium battery safety test, so it is necessary to understand the overcharging mechanism and the current measures to prevent overcharging.

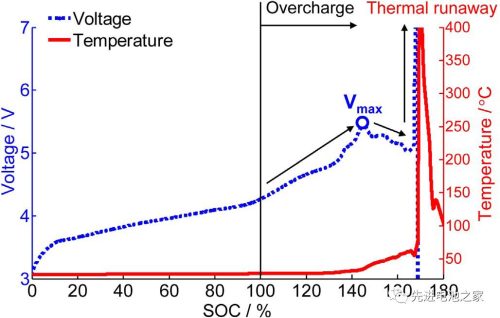

Figure 1 shows the voltage and temperature curves of the NCM+LMO/Gr system when the battery is overcharged. The voltage reaches a maximum at 5.4V, and then the voltage drops, eventually causing thermal runaway. The voltage and temperature curves of ternary battery overcharge are very similar.

When the lithium battery is overcharged, heat and gas will be generated, and the heat includes ohmic heat and heat generated by side reactions, of which ohmic heat is dominant. The side reactions of the battery caused by overcharge are firstly the insertion of excess lithium into the negative electrode, and lithium dendrites will grow on the surface of the negative electrode (the N/P ratio will affect the initial SOC of the growth of lithium dendrites). The second is that excess lithium is extracted from the positive electrode, causing the positive electrode structure to collapse, releasing heat and releasing oxygen. Oxygen will accelerate the decomposition of the electrolyte, the internal pressure of the battery will continue to rise, and the safety valve will open after a certain level. The contact of the active substance with the air further generates more heat.

Studies have shown that reducing the amount of electrolyte can significantly reduce heat and gas generation during overcharging. In another study, when the battery is overcharged without a splint or the safety valve cannot be opened normally, the battery is prone to explosion.

A slight overcharge will not cause thermal runaway, but will cause capacity fade. The study found that when the battery with NCM/LMO hybrid material as the positive electrode is overcharged, the capacity of SOC is lower than 120% without obvious attenuation, and when the SOC is higher than 130%, the capacity will be attenuated significantly.

At present, there are several methods to solve the overcharge problem:

1) The protection voltage is set in the BMS, usually the protection voltage is lower than the peak voltage during overcharge;

2) Improve the overcharge resistance of the battery through material modification (such as material coating);

3) Add anti-overcharge additives to the electrolyte, such as redox pairs;

4) The use of voltage-sensitive membrane, when the battery is overcharged, the membrane resistance is significantly reduced, which plays a role in shunting;

5) The use of OSD and CID design in the square aluminum shell battery is currently a general anti-overcharge design. A similar design cannot be achieved with pouch cells.