Anode materials are the key components of lithium-ion batteries and have an important impact on the performance of lithium-ion batteries. The study found that the granulation method of the negative electrode material has a great influence on its performance.

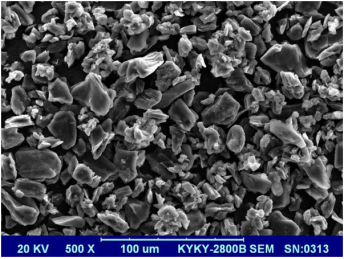

Using coal-based needle coke as raw material, the researchers obtained primary particle anode material by crushing and graphitization, and studied the graphitization mechanism and lithium storage mechanism. The results showed that the primary Coulombic efficiency of the primary particle anode material was 84%. Although the primary particle anode material using needle coke as raw material has high capacity, due to the unique streamlined fiber structure of needle coke, the orientation degree in each direction is different, and the primary particle anode material prepared only by needle coke There are still some defects in electrochemical performance, which is easy to cause battery swelling, and the rate performance is general. At present, the preparation process of anode materials has been gradually improved to improve the processing performance, first Coulomb efficiency and rate capability of anode materials.

Secondary granulation is beneficial to improve the performance of negative electrode materials. The secondary granulation process is to pulverize the aggregate to obtain a small particle base material, and use asphalt as a binder. According to the size of the target particle size, secondary granulation is carried out in the reaction kettle. Secondary granulated anode material. The secondary granulation process of single-particle anode can enrich the number of channels for Li+ intercalation and deintercalation in the lattice, and further improve the rate performance and low-temperature performance of the anode material. Small particles have large specific surface area, many lithium ion migration channels, short paths, and good rate performance. Large particles have high compaction density and large capacity.

Secondary particle anode materials can take into account the advantages of large particles and small particles, and become anode materials with high capacity and good rate performance. In addition, the secondary particle anode material formed by the granulation process can increase the isotropy of the anode material and improve the first Coulomb efficiency and rate performance of the battery.

1. Performance analysis of secondary particle artificial graphite anode material under different binder dosages

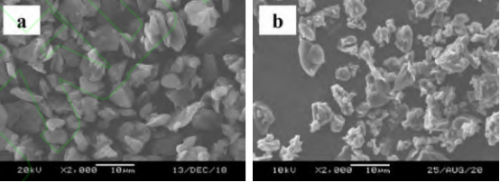

The researchers used coal-based needle coke green coke as raw material and self-made high-performance coal pitch as binder to granulate needle coke green coke to prepare secondary particle artificial graphite anode material with high energy density and rate performance. . Using different analysis methods, the physical and chemical indexes and electrochemical properties of the secondary particle artificial graphite anode material were analyzed when the addition amount of binder pitch was 5% (mass fraction, the same below), 8% and 12%, respectively.

When the addition amount of binder asphalt is 8%, the effect of the granulation process is the most ideal, and the single raw material particles aggregated under the action of binder asphalt have the largest amount of secondary particles. For the graphite anode material, the particle size and tap density of the artificial graphite anode material prepared under this condition are significantly improved.

In terms of electrochemical tests, the first charge specific capacity and first coulombic efficiency of 8% CP-AG at 0.1C current density are 345.7 mAh/g and 95.6%, respectively, which are higher than 5% CP-AG and 12% CP-AG. The first-time charge specific capacity and first-time coulombic efficiency of 8% CP-AG also exhibited higher rate charge-discharge capacity at 1C and 2C current density in the rate performance test.

The coal tar pitch is converted into needle coke and binder pitch, and prepared into secondary particle artificial graphite negative electrode material, which retains the advantage of high capacity of primary particle negative electrode material, and at the same time makes up for the lack of primary particle in rate performance, and can also realize coal High value-added utilization of asphalt.

2. Effect of single particle artificial graphite anode material and secondary particle artificial graphite anode material on battery performance

In order to optimize the performance of power-type lithium-ion batteries, the researchers took LiNi0.5Co0.2Mn0.3O2 (NCM523)/graphite system square batteries as the object, and compared two different power-type anode materials (single particle artificial graphite and secondary particle artificial graphite). ) of the physicochemical differences to analyze the effect of the two anode materials on the electrochemical performance of the battery.

The researchers analyzed the negative electrode materials and assembled batteries from the aspects of physical and chemical indicators, electrochemical impedance, DC internal resistance, constant power charge and discharge at different temperatures, low temperature pulse discharge, rate performance, cycle performance, and high temperature storage performance. The analysis shows that the particle size distribution of the secondary particle artificial graphite anode material is narrower, which improves the kinetic performance and has lower impedance characteristics. At room temperature, the charge-discharge DC internal resistance of the prepared battery is higher than that of single particle artificial graphite. The reduction of anode material preparation is 16.58% and 13.96%, respectively. The secondary particle artificial graphite anode material has better high-current charge-discharge performance and low-temperature performance, and performs better in constant power charge-discharge, low-temperature pulse discharge and rate performance tests; 2500 cycles at 3.00C at 2.8V-4.2V at room temperature , the capacity retention rate is 86.7%, which is 1.5% higher than that of single particle artificial graphite anode. Due to the increased specific surface area of the secondary particle artificial graphite anode material, the high temperature storage performance is slightly reduced. After 30d of full charge storage, the residual capacity and recovery capacity are 1.4% and 1.5% lower than that of the single particle artificial graphite anode material, respectively.

For the negative electrode material, its particle size, morphology, specific surface area, degree of graphitization, tap density, etc. will affect the performance of lithium-ion batteries. Different granulation methods will have a certain impact on the performance of negative electrode materials and lithium-ion batteries. Through comparative analysis, compared with single particle negative electrode materials, the secondary particle negative electrode materials prepared by the secondary granulation process are more superior in performance, and also have better performance. It is explained that the correct evaluation of the properties of materials and the rational selection of materials are also very important for the performance optimization of lithium-ion batteries.