Soft carbon is a carbon material obtained by carbonization at low temperature. When this material is used as a negative electrode material for lithium-ion batteries, it has high lithium intercalation capacity, can achieve close packing, high volume specific capacity, strong compatibility with solvents, and long cycle life. , high safety, strong low temperature charge and discharge capacity and so on. Soft carbon is one of the candidate anode materials for fast-charging lithium-ion batteries, and the development of high-power soft carbon materials is a current research focus. The electrochemical performance of soft carbon mainly depends on its microstructure and significantly depends on the carbonization temperature of the precursor.

1. The effect of pore structure on the lithium storage performance of soft carbon anode

The microstructure of soft carbon includes amorphous structure, turbostratic structure and graphitized structure. Its graphite layer spacing is large, and it has a large number of lithium storage active sites, which is suitable for high-power applications; at the same time, compared with hard carbon, Soft carbon has higher first Coulomb efficiency and smaller irreversible capacity, and is more practical.

In recent years, in order to further improve the electrochemical performance of soft carbon, researchers have made many attempts and found that increasing the porosity of soft carbon is beneficial to the improvement of its reversible capacity. Jo et al. used phosphoric acid to pore-forming petroleum coke-based soft carbon, and its reversible capacity was increased from 337mAh/g to 397mAh/g.

However, the effect of increased porosity is not all favorable, it will increase the contact area between the electrode material and the electrolyte, resulting in a lower first Coulombic efficiency. Therefore, in-depth analysis of the structure-activity relationship between the soft carbon pore structure and its electrochemical performance is required.

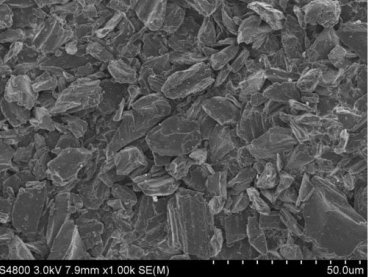

The researchers used two types of needle coke (Jinzhou needle coke and Japanese JEF needle coke) as raw materials to prepare soft carbon materials with similar morphologies, the same interlayer spacing and degree of lattice defects, but different pore structures. Electrochemical methods such as GCPL, EIS, and GITT were used for analysis, and the effect of pore structure on the lithium storage performance of soft carbon was systematically studied.

The results show that among the two types of needle coke, Japanese JEF needle coke is an ideal soft carbon precursor material, and the micropores in its structure (content as high as 63%) can significantly enhance the lithium storage performance. First, the micropores contribute less to the decomposition of the electrolyte in the SEI formation reaction, which will not lead to the decrease of the first Coulombic efficiency, and at the same time, it can avoid the passivation of the electrode and improve the cycle stability of the electrode.

Second, micropores can serve as active sites for lithium storage, improve the diffusion coefficient of lithium ions in soft carbon, and increase the capacity contribution of the adsorption reaction with fast kinetics, thereby achieving high reversible capacity and rate capability.

2. Effect of carbonization temperature on lithium storage performance of soft carbon anode

Compared with graphite, amorphous carbon has more active sites, anisotropic structure, and wider interlayer spacing, which can provide higher reversible capacity and rate capability. Hard carbon and soft carbon are typical amorphous carbons. Hard carbon is made of organic precursors with fully cross-linked macromolecules as raw materials, with few graphite crystallites, disordered arrangement, and cannot be graphitized during the carbonization process; while soft carbon graphite The crystallites are arranged in a quasi-parallel manner and can be graphitized during high temperature carbonization (>2000°C).

Among them, hard carbon has attracted extensive attention due to its high lithium storage capacity (eg, epoxy resin-based hard carbon has a specific capacity of up to 700 mAh/g). However, in practical application, hard carbon exhibits extremely low first Coulombic efficiency and large voltage hysteresis, which is difficult to meet commercial demands.

At present, because the properties of soft carbon are between hard carbon and graphite, and the microstructure is adjustable, it has gradually been paid more attention. Wang et al. used a solvothermal method to synthesize a toluene-based soft carbon (0.377 nm) with a wide interlayer spacing, which could provide a reversible specific capacity of 390 mAh/g with excellent rate capability. Jo et al. mentioned above significantly increased the reversible specific capacity of petroleum coke-based soft carbon by pore-forming treatment with phosphoric acid.

These results suggest that rational design of the microstructure is the key to the development of high-performance soft carbon anode materials.

Earlier research results showed that the microstructure of carbon materials is greatly affected by the carbonization temperature of the precursor. In view of this, the researchers used needle coke-derived soft carbon as a model material, with the help of scanning electron microscopy (SEM) technology, X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD), laser Raman (Raman) spectroscopy and Nitrogen isothermal adsorption and other characterization methods can track its structural evolution at carbonization temperature of 900-1700 °C, and analyze its structural evolution by electrochemical characterization methods such as cyclic voltammetry (CV), constant current charge-discharge (GCPL), and alternating current impedance (EIS). Correlation of microstructure and kinetics of lithium storage.

The results show that, with the increase of carbonization temperature, the microstructure of soft carbon will have three distinct dominant stages, namely, the dominant stage of amorphous structure, the dominant stage of turbostratic structure and the dominant stage of graphitized structure, which significantly affect its microstructure. Electrochemical behavior.

First, the amorphous structure dominates the stage (900°C≤t<1300°C). The soft carbon in this carbonization temperature range is mainly amorphous, with abundant pores, high specific surface area and graphite interlayer spacing. With the increase of carbonization temperature, the amorphous structure is gradually transformed into a graphitized structure, the porosity and specific surface area are greatly reduced, and the content of heteroatoms is rapidly reduced and the interlayer spacing is reduced. The lithium storage process of soft carbon is mainly the adsorption reaction of lithium ions in its defects, edges and micropores. The reaction kinetics are fast, but the reversible capacity is less (less micropores), and the first Coulombic efficiency is very low (<60%). ) is difficult to be directly used as a fast-charging negative electrode, and it needs to be coated.

Second, the turbostratic structure dominates the stage (1300°C≤t≤1500°C). Compared with the dominant phase of the amorphous structure, the soft carbon in this carbonization temperature range is mainly a turbostratic structure, the porosity and specific surface area are greatly reduced, and the interlayer spacing remains unchanged with the escape of heteroatoms. With the increase of carbonization temperature, the transformation rate of amorphous structure to graphitized structure decreased, and the specific surface area decreased at the same time. Soft carbon gradually increases the proportion of lithium intercalation reaction in the process of lithium storage. At the same time, it has high reversible capacity and rate performance, and Coulombic efficiency > 70%, which can be used as a fast-charging negative electrode.

In addition, in this temperature range, the first Coulombic efficiency has a greater dependence on the surface area, and significantly affects the reaction kinetics. Therefore, it is necessary to fine-tune the carbonization temperature to improve the Coulombic efficiency and avoid the decrease in rate performance caused by electrode passivation.

Finally, the graphitized structure dominates the stage (t>1700°C). The soft carbon in this carbonization temperature range is mainly graphitized, the pores basically disappear, and the specific surface area is further reduced. With the increase of carbonization temperature, the defects of soft carbon are further repaired, and the long-range order degree is improved at the same time. The first Coulombic efficiency of soft carbon is further improved, but the lithium storage process is mainly an intercalation reaction, the reaction kinetics are slow, and the reversible capacity is low, making it difficult to be used as a fast-charging anode.