In recent years, the rapid development of new energy vehicle technology has put forward higher and higher requirements for the energy density of lithium-ion power batteries. Ternary cathode materials, especially high-nickel materials, have relatively high specific energy and working voltage, and become the most promising cathode materials at present.

The general high-nickel ternary cathode material is mainly composed of secondary particles in the form of agglomeration and polycrystalline. In high-nickel materials, with the increase of Ni content, the gram capacity of the material also increases.

However, high nickel secondary particle materials still have the following problems:

①Due to the low bulk density of the positive electrode material formed by secondary agglomerates, the compaction density of the resulting pole piece is low, which reduces the specific energy of the battery;

②The large residual stress in the primary particles inside the secondary spherical particles can easily lead to micro-cracks due to the phase transition during the charging and discharging process, which in turn affects the thermal stability and cycle life of the battery;

③ The particle size of the primary particles inside the material is small, the structure is incomplete, the interface side reaction is difficult to control under the condition of high voltage charge and discharge, and the structure collapse is easy to occur;

④ During the process of pressing the pole piece, the particles are easily broken, and the electrolyte penetration is serious, which leads to side reactions such as gas production, and the safety performance is greatly reduced.

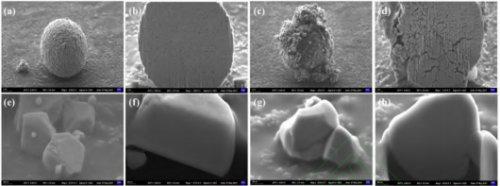

SEM and FIB-SEM images of polycrystalline 811 and single crystal C811.

Compared with secondary spherical particles, single crystal ternary cathode materials have the following advantages:

① There is no intergranular interface inside the single crystal particles, and no intergranular breakage occurs after multiple charge-discharge cycles;

② The specific surface area of single crystal particles is small, the contact area with the electrolyte is small, and the side reactions are small;

③The single crystal material has high mechanical strength, is not easy to be broken during the compaction process, and has high compaction density;

④Single crystal material particles are small and can be fully contacted with conductive agent and binder to form a better conductive network, which is conducive to Li+ and electron transport.

Therefore, more and more researchers have turned their attention to single-crystal ternary cathode materials.

High temperature calcination method: Increasing the calcination temperature can promote ion migration and increase the grain growth rate. But increasing temperature must increase the excess lithium content to offset lithium volatilization.

Multi-step calcination method: Multi-step calcination can optimize grain growth and crystal structure, and obtain high-nickel single crystal materials with good particle size and low cation mixing. The crystals formed by the multi-step method are much larger than those formed with only one high temperature step, but require milling to reduce agglomeration after the first step of calcination.

Molten salt method: Molten salt synthesis, i.e. adding a large amount of salt to the precursor during calcination. In molten salts, atoms dissolve and diffuse, providing a pathway for crystal growth and lowering the calcination temperature, thereby reducing cation mixing and particle agglomeration, but requires washing to remove excess salt. Molten salt synthesis results in a lower degree of agglomeration and cation mixing.

Most of these methods follow the mechanism of dissolution-recrystallization, that is, the polycrystalline secondary particles disintegrate under high temperature conditions, and the primary particles are exposed. With the increase of temperature and the prolongation of holding time, the primary particles grow slowly A crystal plane appears and a single crystal is formed.

In terms of energy density, single crystal materials can simultaneously increase capacity and working voltage, thereby increasing energy density. From the perspective of the main products currently in practical application, the energy density of single crystal 6 series can basically equal the high nickel 8 series. In terms of safety performance, the single crystal ternary has obvious advantages. There is no grain boundary inside the single crystal, which can effectively improve the battery cycle performance and slow down the capacity decay. In terms of product structure, the 5-series ternary still occupies a dominant position in the mono market, but its market share has declined; the mono-6-series has accelerated its volume due to its excellent overall performance and low-cost advantages, and its market share has gradually expanded.