When the lithium-ion battery is charged, Li+ is de-intercalated from the positive electrode and inserted into the negative electrode; but in some abnormal situations: such as insufficient space for lithium intercalation in the negative electrode, too much resistance of Li+ intercalation in the negative electrode, and Li+ is de-intercalated from the positive electrode too quickly but cannot be embedded in the same amount. When an abnormality such as the negative electrode occurs, the Li+ that cannot be embedded in the negative electrode can only obtain electrons on the surface of the negative electrode, thereby forming a silver-white metallic lithium element, which is often referred to as lithium precipitation. Lithium precipitation not only degrades battery performance and greatly shortens cycle life, but also limits the battery’s fast charge capacity and may cause catastrophic consequences such as combustion and explosion. In this paper, we discuss from macroscopic lithium-ion batteries, working conditions, gradients existing inside batteries, electrochemical tests, safety tests, etc.), microscopic (electrodes, particles, microstructures, etc.) and atomic (atoms, ions, molecules, activation energy barriers, etc.) The following issues are clarified on the scale:

(1) What is the “fuse” for the lithium evolution reaction?

(2) What are the experimental phenomena of the lithium evolution reaction?

(3) What are the macroscopic morphologies of metallic lithium deposited on the negative electrode surface under different conditions? What is the direct experimental evidence for side effects?

(4) What is the relevant mechanism of battery aging caused by lithium evolution reaction? What is the capacity decay curve (i.e., how the capacity retention varies with the number of cycles) during this process?

(5) In the practical application of lithium-ion batteries, what safety hazards does the lithium-evolution reaction bring?

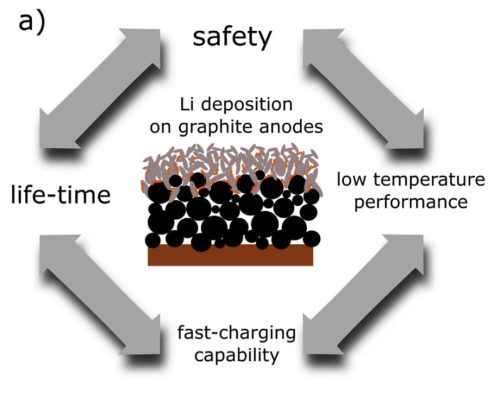

With the rapid development of lithium-ion battery-related technologies, diversified energy storage needs continue to emerge, and people have put forward higher requirements for future lithium-ion batteries:

(1) Longer life (more than 10 years battery life is required for electric vehicles);

(2) Excellent fast charging performance (it only takes 20 minutes to charge to 80% of the state of charge);

(3) Excellent low temperature cycle performance and capacity recovery ability;

(4) Impeccable safety performance.

Interestingly, these four high-profile battery performances are closely related to the lithium-evolution side reaction, and the battery aging process and anode reaction kinetic changes caused by this side reaction have a huge impact on the above four performances.

1. When does the lithium deposition side reaction occur?

When a lithium-ion battery is charged, Li+ is deintercalated from the positive electrode, and these Li+ diffuses in the electrolyte to the surface of the negative electrode and intercalates into the negative electrode material. Taking the graphite negative electrode as an example, when the negative electrode potential drops to 200-65 mV vs. Li+/Li, the lithium intercalation process occurs; as the charging continues, the negative electrode potential drops below 0 V vs. Li+/Li, and lithium occurs. The deposition side reaction, at this time, the lithium deposition side reaction of the negative electrode and the lithium intercalation reaction are carried out simultaneously. Considering the effect of polarization, the lithium deposition side reaction occurs when the sum of the equilibrium potential and the overpotential (from ohmic resistance, charge transfer, and diffusion processes) is negative with respect to the Li+/Li pair.

2. Factors affecting the side reactions of lithium deposition?

1. The positive and negative electrodes of the lithium-ion battery and the metal lithium reference electrode are formed into a three-electrode system as shown in Figure 2(b) for charging test, and the change of the negative electrode potential with the full battery voltage is shown in Figure 2(a) . The study found that when the state of charge (SOC) and charging current density are larger, and the test temperature is lower, the potential of the graphite negative electrode will be more negative, and the side reaction of lithium deposition on the negative electrode surface will be more likely to occur.

2. Lithium battery level: Increasing the N/P ratio within a certain range helps limit the state of charge of the negative electrode to a lower level, thereby reducing the battery aging rate and making the battery internal resistance increase more slowly.

3. Anode reaction kinetics: The lithium evolution reaction is also affected by the type, morphology, and conductivity of the anode material. They affect the degree of anode polarization from the perspective of diffusion mass transfer or charge transfer, thereby affecting the anode potential and anode reaction.

4. Activation energy: The activation energy that solvated lithium ions need to overcome when diffusing in the electrolyte is negligible, while the activation energy that solvated lithium ions need to overcome during desolvation, diffusion through the SEI membrane, and charge transfer is negligible. Highest. With the progress of the charging process, the number of Li+ embedded in the negative electrode gradually increases, the activation energy that needs to be overcome when Li+ diffuses in the negative electrode active material increases, and the solid-phase diffusion becomes more difficult.

5. Temperature: According to the Arrhenius formula, when the battery is cycled at low temperature, the lithium evolution reaction has a larger reaction rate than the lithium intercalation process, that is, the negative electrode is more prone to lithium evolution reaction at low temperature. This has been verified by experimental observations of more negative potentials of graphite anodes at low temperatures. In addition, the charge transfer and solid-phase diffusion at low temperature are also slower, and the reaction rate between the metal lithium deposited on the surface of the negative electrode and the electrolyte also decreases.

6. Charging rate: The charging current rate determines the lithium ion flux on the negative electrode material per unit area. When the solid-phase diffusion process of Li+ in the negative electrode is slow (for example, when the temperature is too low, the state of charge is high, or the diffusion of Li+ in the material needs to overcome a large activation energy), and the charging current density is too large, the negative electrode surface Lithium evolution reaction occurs. When other conditions remain unchanged, and the current density increases to a certain threshold, the negative electrode potential becomes negative, accompanied by the onset of the lithium evolution reaction.

3. Collecting experimental evidence for lithium deposition side reactions from different perspectives

Dr. Margret Wohlfahrt-Mehrens selected five commercial lithium-ion batteries that have been widely studied in recent years, and numbered them as battery 1-battery 5, and collected experimental evidence for the side reactions of lithium deposition from the following four perspectives: (1) Aging characteristics; (2) voltage curve; (3) physicochemical properties of batteries; (4) physicochemical properties of electrodes.

By comparing lithium-ion batteries of the same model, the researchers found that the side reaction of lithium deposition made the battery have a faster aging rate, and its battery capacity, energy density, and energy efficiency were significantly attenuated.

1. Detecting the extent of lithium deposition side reactions by analyzing the coulombic efficiency: The battery aging mechanism involving lithium deposition side reactions reduces the coulombic efficiency of the battery, so monitoring the extent of lithium deposition side reactions by accurately measuring the coulombic efficiency of lithium-ion batteries is a Feasible method. The metal lithium generated in the side reaction of lithium deposition reacts with the electrolyte to form an SEI film, which reduces the coulombic efficiency. It should be noted that the drop in Coulombic efficiency is not entirely caused by the lithium deposition side reaction. For example, the shedding of electrode active materials, the formation of SEI film and the blockage of micropores on the electrode surface will increase the internal resistance of the battery and cause irreversible capacity loss, which will reduce the Coulombic efficiency.

2. The apparent activation energy of the side reaction of lithium deposition is obtained by analyzing the Arrhenius curve: by performing charge-discharge cycle tests on lithium-ion batteries at different temperatures, the Arrhenius can be obtained from the capacity decay curves at different temperatures. s curve (Figure 4). When the temperature is high, the side reaction of lithium deposition does not occur, the dissolution of the positive electrode active material and the formation of the SEI film on the positive and negative electrode surfaces are accelerated with the increase of temperature, and the aging rate of the battery is also accelerated; when the temperature is low, the lithium deposition Side reactions take the stage, which makes the aging mechanism abruptly, because the lithium deposition side reactions intensify as the temperature decreases, so the battery aging rate accelerates with the decrease in temperature. In summary, the Arrhenius curve of Li-ion batteries is V-shaped as shown in Fig. 4, and its slope is the negative value of the apparent activation energy (-Ea) during aging. The lithium deposition side reaction has a negative apparent activation energy.

4. Gradients of various factors in lithium-ion batteries and the morphology of lithium metal deposited on the negative electrode

In the actual charging or aging process, the temperature, state of charge, and charging current density are often unevenly distributed on the surface of the negative electrode inside the lithium-ion battery. The gradient formed by these factors inside the battery causes the lithium deposition side reactions to proceed at different rates at various points on the surface of the negative electrode, resulting in the deposition of non-uniform lithium layers. When the localized temperature of the negative electrode surface is low, the state of charge is high, and the current density is high, the lithium deposition side reaction tends to proceed rapidly in this region, resulting in more severe lithium deposition than other regions.

Lithium precipitation reaction is the fatal culprit that causes the increase of internal resistance, capacity attenuation and Coulomb efficiency drop of lithium-ion batteries, and may even lead to safety hazards such as fire and explosion in severe cases. Based on the previous studies on 5 types of commercial lithium-ion batteries, this paper introduces the causes, phenomena, and product morphology of lithium deposition side reactions, and discusses the use of different characterization methods to collect direct experimental evidence and indirect experiments for lithium deposition side reactions. method of evidence. Subsequently, the review presents battery aging mechanisms involving lithium deposition side reactions, and summarizes methods for detection and prevention of related safety hazards.

In fact, in order to reflect the real life of Li-ion batteries as accurately as possible under practical application conditions, electrochemical tests need to be performed under conditions that combine various aging mechanisms, such as cycle-life aging tests after the calendar-life aging phase. Such cases are more complex and require further investigation. In addition, optimizing the charging and discharging conditions, designing the battery configuration and designing new anode materials are also important ways to alleviate the lithium evolution reaction.