The production process of negative electrode materials is long and there are many kinds of raw materials, and the negative electrode factory has certain bargaining power. Due to the long process required for particle size and morphology design in the processing of artificial graphite anode materials, it needs to go through steps such as pretreatment, pyrolysis, ball milling, external graphitization, and screening.

In the production process, the composition of anode material products is relatively complex, including a variety of cokes and additives. Battery companies usually cannot fully grasp the complete cost of artificial graphite suppliers. Therefore, artificial graphite suppliers have stronger negotiating power than other material links.

The technical route of artificial graphite anode is relatively mature, and more barriers are concentrated in the granulation process.

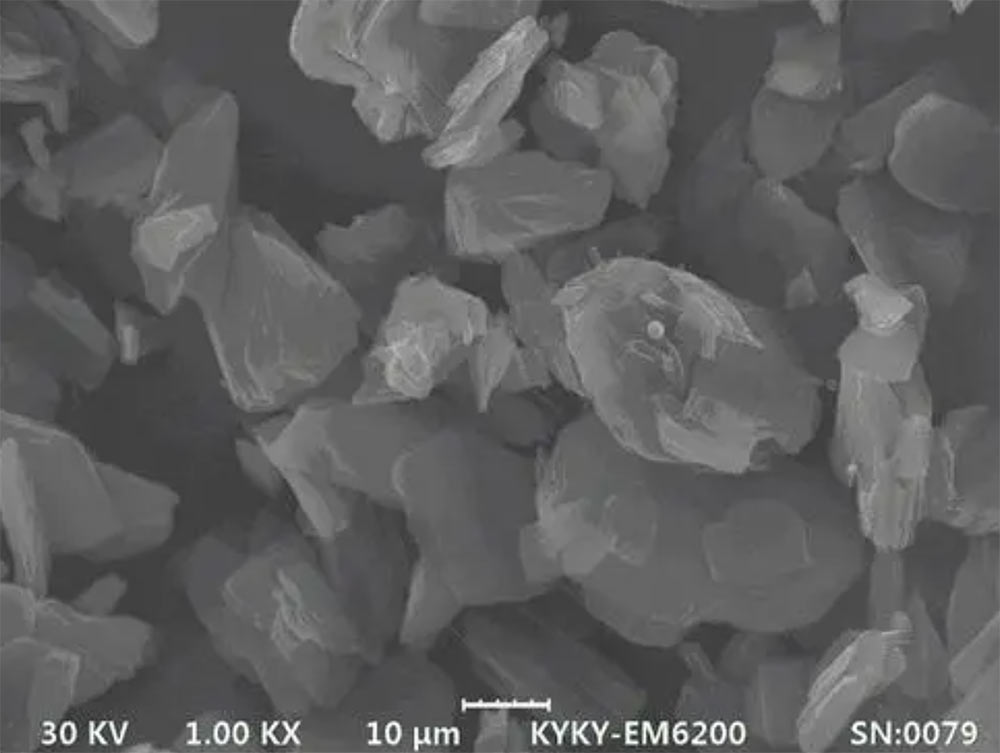

The theoretical specific capacity of artificial graphite is 372mah/g, and the current mainstream products can achieve 345-355mah/g. The production process is to crush, granulate, graphitize and screen aggregates and binders. The pulverization-spheroidization-mixing-screening-magnetic separation process of natural graphite negative electrode, artificial graphite negative electrode has three more key processes: granulation-graphitization and secondary granulation. The basic process flow of each company is the same, but they will There are certain differences, such as carbonization link and modification link, screening times, etc.

Relatively speaking, each process of artificial graphite negative electrode is relatively mature in technology, so it is more about process optimization and cost comparison. It is necessary to balance the advantages of small particles in rate performance and cycle life as well as the disadvantages in first efficiency and compaction density, and also weigh the influence of particle morphology on rate and low temperature performance; high-end artificial graphite is generally carried out after graphitization. Secondary granulation, paste 7-8 small granules, taking into account the expansion performance and energy density.

Graphitization is an extension of the traditional carbon industry, so foreign companies such as Hitachi Chemical and Mitsubishi Chemical are the leading companies in the negative electrode. From the current point of view, the graphitization technology is mature but has a great impact on cost control. High-end artificial graphite usually uses ultra-high temperature The graphitization process is more expensive.