Since the origin of human beings, the pursuit and exploration of energy have never stopped. Many scientists have dreamed of inventing perpetual motion machines to solve the problem of energy supply once and for all. However, the discovery of the first law of thermodynamics made people realize that “perpetual motion machines” can never be realized, so human beings can only continue to embark on a long journey to explore energy.

Throughout history, human beings have experienced three major energy utilization stages, namely “fire and fuelwood”, “coal and steam engine” and “petroleum and internal combustion engine”. In ancient Greek mythology, Prometheus stole fire from Apollo, the sun god, to bring civilization to mankind. In China, more than 10,000 years ago, “the divine bird and owl pecked the wood, and the fire came out. the legend of. Xunzi said: “The nature of a gentleman is not different, and he is good at things.” For tens of thousands of years, human beings have continued their wisdom and civilization with the help of the inherent power of energy. From fuelwood to coal, oil, and natural gas, human beings have been exploring more efficient and convenient energy forms.

With the large-scale use of fossil energy, the energy crisis and environmental pollution problems have gradually become prominent, and renewable energy such as solar energy, wind energy, thermal energy, and tidal energy have emerged in the wisdom of human beings. From the application of non-renewable resources to renewable resources, human beings have glimpsed the tip of the iceberg of ideal energy that is “inexhaustible”. How to utilize and control these energy sources requires effective energy conversion and energy storage technologies.

Nowadays, the human energy process has entered the stage of “new energy and sustainable development”. New energy vehicles are on the rise, and the importance of power batteries and energy storage systems has been pushed to an unprecedented historical height. The performance of existing power batteries and energy storage devices is closely related to the performance of their components. In order to improve their overall performance, researchers need to have a deeper understanding of the physical and chemical properties of the component materials. The research would be more challenging if these materials were sensitive to air and moisture.

Thermo Scientific CleanConnectTM has developed an inert gas/vacuum protected sample transfer system for air-sensitive samples, opening up new horizons for air-sensitive material characterization. The inert gas/vacuum protected sample transfer workflow can help researchers expand the research boundaries of air-sensitive materials and explore more unknown areas.

Applications

Some battery materials (such as lithium metal, sulfur-based solid electrolytes, fully charged anodes, etc.) are very sensitive to moisture and oxygen, so special protection is required during sample handling and transfer in order to obtain real morphological and structural information of the material . In addition, the characterization of solid-state batteries also needs to be carried out in the absence of air: for example, characterization of solid-state battery materials, in situ experiments to characterize the lateral growth morphology of dendrites in the SEI (solid-electrolyte interface), and volume expansion due to silicon materials. The resulting SEI instability experiments, etc.

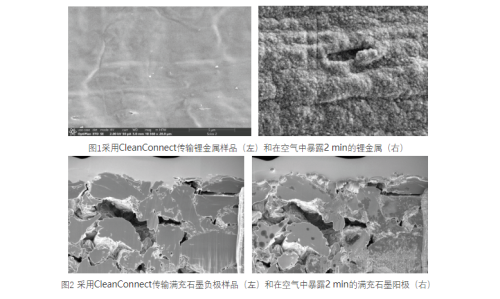

The following two figures compare the morphologies of lithium metal and fully charged graphite anode samples protected by the CleanConnect system and exposed to air. The results show that CleanConnect effectively protects the samples from air/moisture contamination, thereby helping researchers to obtain the true shape. The topography and structure information can be used to realize more in-depth analysis and research of samples.

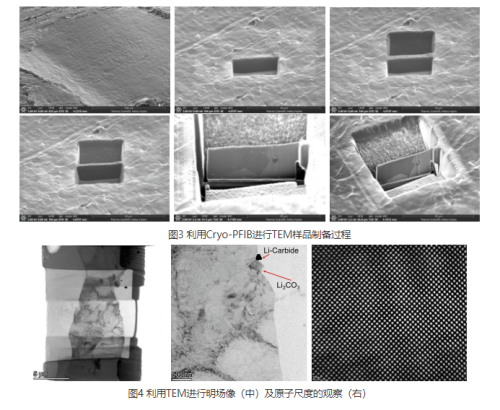

If atomic-scale characterization of lithium metal is desired, TEM sample preparation is required. Conventional Ga ions react with Li metal at room temperature, making it difficult to process Li metal. The xenon plasma gas source PFIB (Plasma FIB) developed by Thermo Scientific can realize the non-destructive preparation of lithium metal transmission samples. To avoid surface oxidation caused by Li metal exposure to air, CleanConnect was used for sample transfer, followed by Cryo-PFIB technique for sample freezing preparation and further observation.

Figure 3 shows the TEM sample preparation process of lithium metal samples using Cryo-PFIB technology at -178 °C and the morphology information of the samples observed in TEM. Figure 4 shows the distribution of Li carbides and Li2CO3 in the TEM bright field image. Using high-resolution imaging, a clear arrangement of lithium atoms can be seen. It can be seen that the sample is not damaged or oxidized during the cutting and transfer process.

In addition to being used in air-sensitive electrode materials such as sodium-ion batteries, sodium-sulfur batteries, and solid-state battery materials, CleanConnect is also very suitable for air-sensitive materials such as magnesium-aluminum alloys, perovskite materials, metal-organic framework materials, and catalysts. characterization. Whether in the search for alternative energy sources or in the development of stronger, lighter materials and sophisticated nanotechnology research, enabling instrumentation and workflows are needed to enable deeper research characterization needs to advance science and technology .

Product description

The CleanConnect Inert Gas/Vacuum Shielded Sample Transfer System is compatible with most Thermo Scientific SEM and dual beam EM systems. It mainly consists of a sample loading chamber, a gate valve unit, a vacuum control device, a sample transfer chamber and a transfer rod. CleanConnect’s vacuum system can be integrated with SEM or dual beam electron microscope, no additional vacuum pump is required, and the vacuuming process can be completed in only 60s. Different from the traditional sample transfer rod, CleanConnect innovatively uses inert gas for sample protection, so that the transfer chamber continuously maintains positive pressure and maximizes the isolation of the sample from the air. The air pressure gauge equipped with the CleanConnect system can display the air pressure in the transfer chamber in real time, so that the user has a clear understanding of the air pressure state of the sample. The positive pressure of CleanConnect can be maintained for more than ten hours, which can realize long-term and long-distance transfer of samples.